In the world of stone machining, where the ancient meets the ultra-modern, one technology has quietly revolutionized workshops worldwide: the 3-axis CNC router. While advanced multi-axis systems capture imagination with their complex capabilities, it's the humble yet powerful 3-axis machine that forms the backbone of stone fabrication. From simple signage to intricate architectural elements, these versatile systems—available in single, dual, triple, and even quad-head configurations—handle the majority of stone machining tasks with remarkable efficiency and precision.

|

|

|

|

Understanding the Basics: Why 3 Axes Still Dominate

The X, Y, and Z linear axes of a standard CNC router provide fundamental movement: left-right, forward-backward, and up-down. This straightforward approach offers several enduring advantages:

The Multi-Head Spectrum: Matching Configuration to Production Needs

Single-Head Machines: The Precision Specialists

The entry point for many workshops, single-head 3-axis routers excel where focus and flexibility matter most. Perfect for custom jobs, prototype development, and smaller operations, they offer:

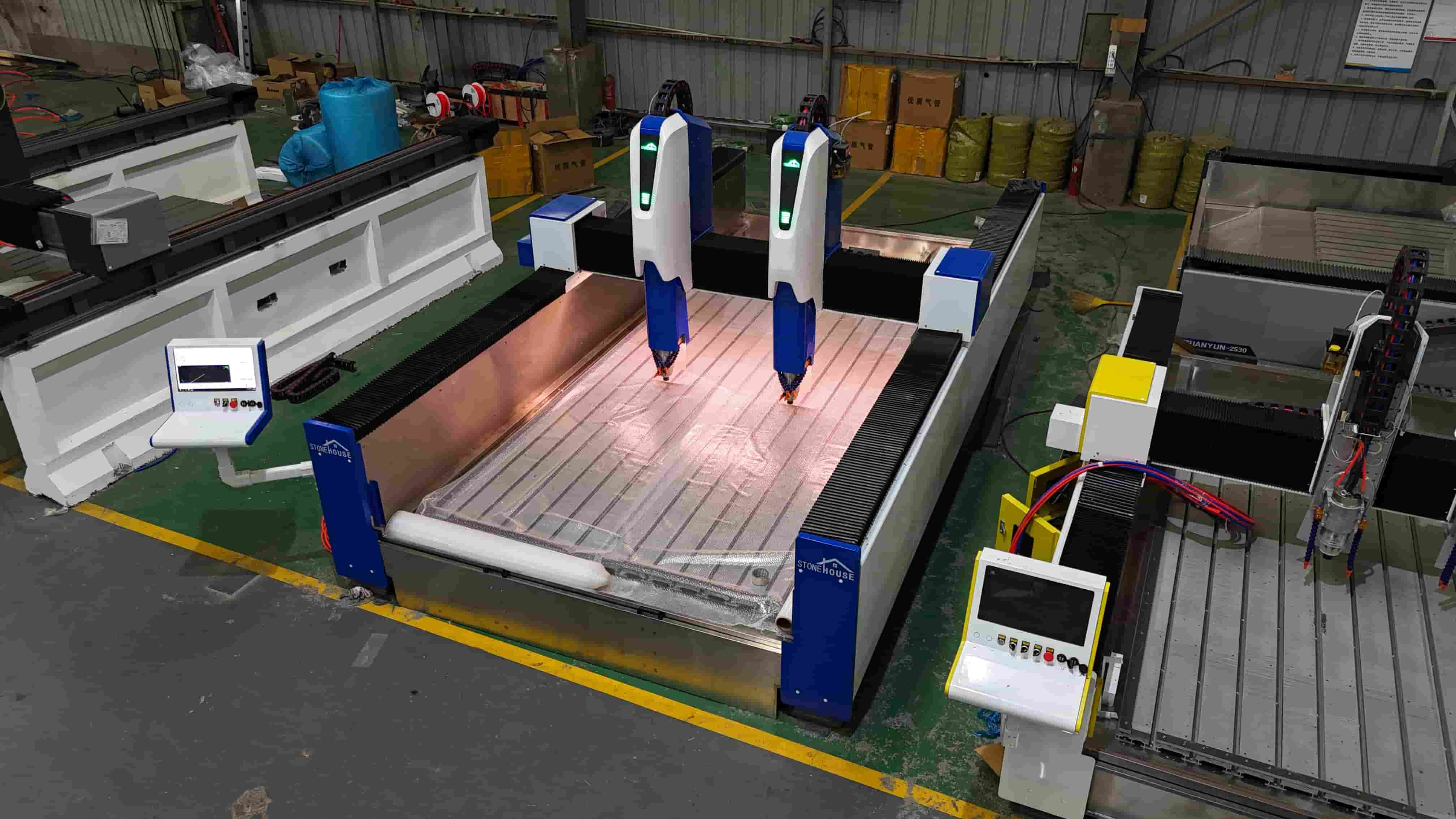

Dual-Head Systems: The Balanced Performers

For growing businesses seeking to increase output without sacrificing flexibility, dual-head configurations offer the perfect middle ground. These machines typically feature:

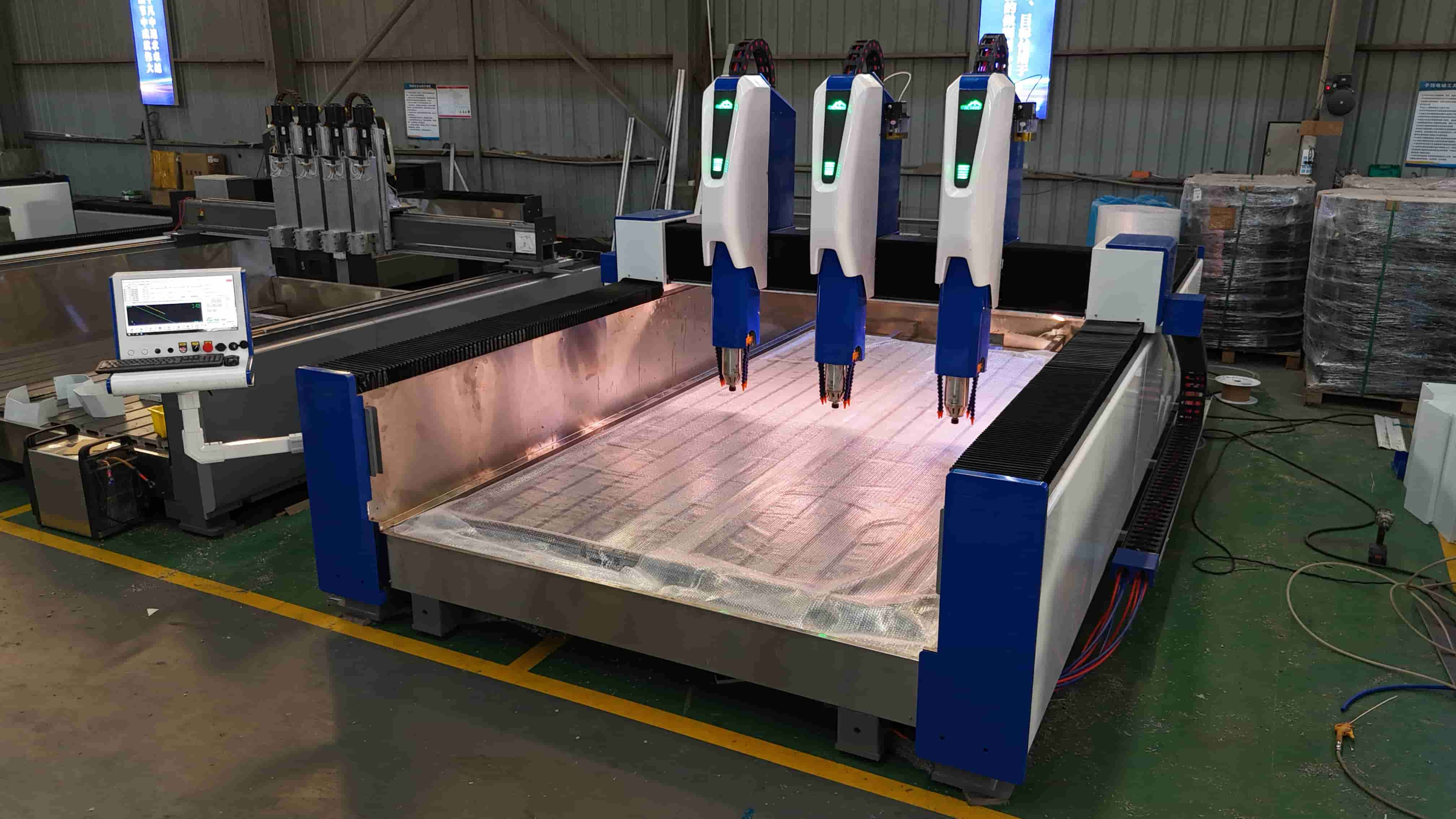

Triple and Quad-Head Machines: The Production Powerhouses

At the industrial end of the spectrum, multi-head routers transform production economics:

Technical Evolution: Modern 3-Axis Capabilities

Today's 3-axis stone routers have evolved far beyond their predecessors:

Advanced Spindle Technology:

Enhanced Structural Design:

Smart Control Systems:

Material Versatility: Beyond Just Stone

While optimized for stone, modern 3-axis routers handle diverse materials:

Economic Considerations: ROI Across Configurations

Single-Head: Best for low-volume, high-variety shops. ROI through versatility and customization premium.

Dual-Head: Optimal for businesses experiencing growth. ROI through balanced productivity and flexibility.

Multi-Head (3-4): Reserved for dedicated production environments. ROI through volume economics and labor reduction

The choice between configurations often comes down to throughput requirements versus job variety. Many successful shops operate multiple machine types to cover different market segments.

Industry Applications: Where 3-Axis Excels

The Future of 3-Axis Technology

Despite the allure of more complex systems, 3-axis routers continue to evolve:

Conclusion: The Right Tool for Countless Jobs

The 3-axis CNC router, in its various multi-head configurations, remains the undisputed workhorse of stone fabrication. Its enduring popularity stems from a perfect balance of capability, reliability, and accessibility. Whether you're an artist creating one-of-a-kind pieces, a fabricator supplying local projects, or an industrial producer meeting global demand, there exists a 3-axis configuration perfectly suited to your needs.

In an industry that venerates both ancient craftsmanship and cutting-edge technology, these machines represent a beautiful synthesis: they provide the precision and repeatability of digital technology while enabling human creativity to flourish in design and application. As technology advances, one truth remains: the fundamental need to efficiently transform raw stone into useful and beautiful objects will ensure the 3-axis router's place in workshops for decades to come.

leave a message

Scan to Wechat :

Scan to WhatsApp :