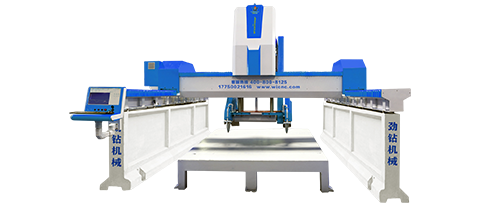

Tailored to address the critical challenge of breakage in large-format stone engraving, our Automatic Flip-Table Stone Engraving Machine revolutionizes safe and efficient processing of oversized stone workpieces.

Read More

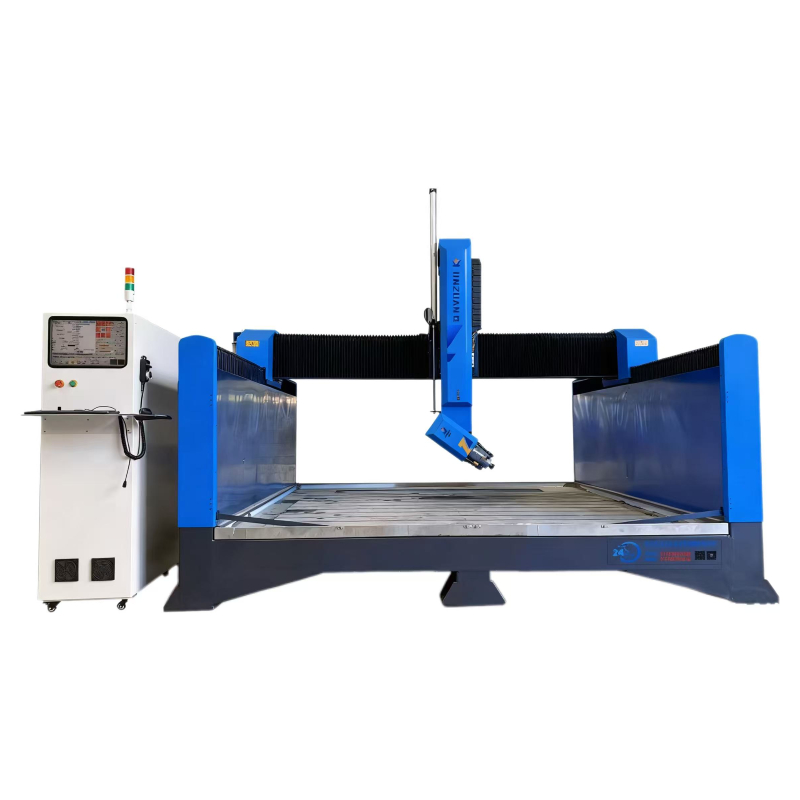

Engineered to solve the long-standing challenge of high-angle stone processing, our 4-Axis CNC Swing-Head Stone Engraving Machine stands out as a specialized solution for arc slabs, flower caps, and irregularly shaped stone workpieces.

Read More

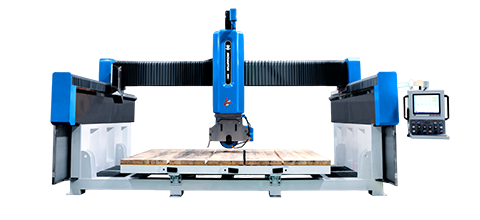

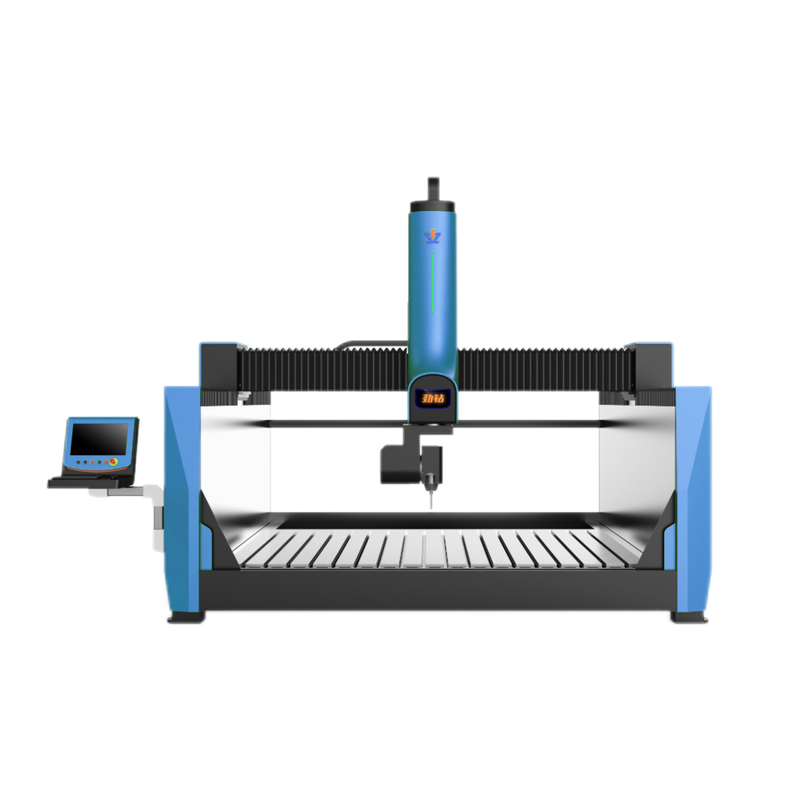

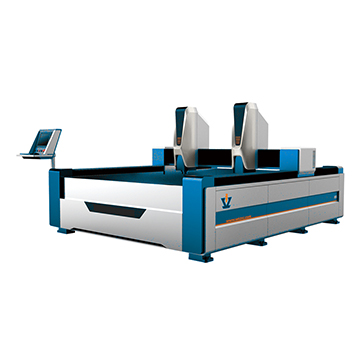

The 5-axis bridge integrated cutting machine is a state-of-the-art industrial solution engineered for high-precision cutting across diverse materials. Combining a robust bridge structure with advanced 5-axis simultaneous motion technology, it delivers superior accuracy, speed, and stability for both complex shapes and large-scale cutting tasks. Equipped with intelligent CNC controls and durable components, making it a reliable choice for factories, processing plants, and fabrication workshops globally.

Read More

Engineered exclusively for the high-end stone processing industry, our 5-Axis CNC Stone Engraving Machine redefines the boundaries of stone craftsmanship by enabling ultra-precise 3D carving and complex shape processing.

Read More

Tailored exclusively for the stone processing industry, our Four-Head CNC Stone Engraving Machine is a revolutionary solution designed to boost production efficiency while maintaining exceptional precision.

Read More

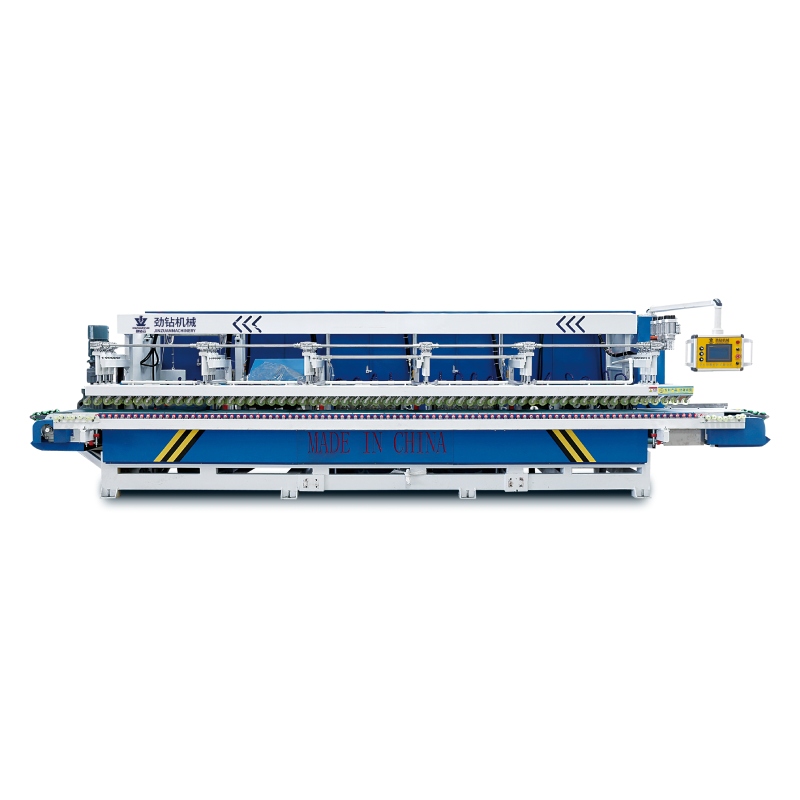

Crafted specifically for the stone processing industry, our Automatic Stone Edging Machine is a game-changer in refining stone edges to achieve flawless, professional finishes.

Read More

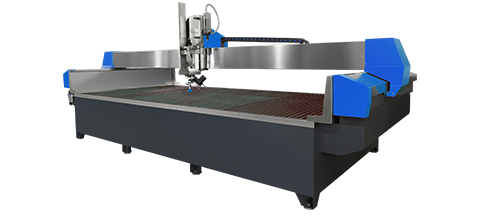

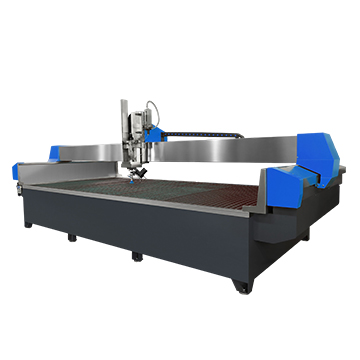

Engineered specifically for the stone processing industry, our High-Pressure Water-Jet Cutting Machine redefines precision, versatility, and efficiency in stone cutting tasks.

Read More

Tailored specifically for the stone processing sector, our Intelligent Stone Engraving Machine stands as a game - changer in realizing versatile and high - precision stone decoration and functional processing. This cutting - edge equipment combines advanced intelligent control systems with high - performance engraving mechanisms, enabling it to effortlessly tackle a wide array of stone processing tasks—from intricate floral carvings and delicate lettering to standardized blind brick engraving.

Read More

Designed exclusively for the stone processing industry, our Bridge-Type Double-Beam Profiling Machine redefines efficiency and precision in stone shaping tasks. This advanced equipment integrates robust double-beam construction with intelligent copying technology, enabling seamless replication of complex patterns, curves, and profiles on a wide range of stone materials—including granite, marble, quartz, and artificial stone.

Read More

Designed exclusively for the stone processing industry, this 2-in-1 Flat & Relief CNC Engraving Machine integrates two core functions—flat engraving and 3D round carving—into a single, high-performance system. It eliminates the need for multiple machines, significantly reducing workshop space occupancy and equipment investment costs while boosting production efficiency.

Read MoreCompany established in

Every equipment undergoes multiple strict quality inspections before delivery. We adopt high-hardness steel frames, imported servo motors, and wear-resistant components, ensuring stable performance and long service life.

Our product line covers the entire stone processing chain—from cutting and shaping to engraving and finishing .This one-stop supply eliminates the need for customers to cooperate with multiple suppliers, simplifying procurement processes and reducing overall costs.

All equipment is equipped with advanced CNC systems, supporting high-precision processing and compatibility with mainstream design software. We also offer flexible customization—such as adjusting working areas, or modifying cutting depths—to meet diverse.

With 10+ years of manufacturing experience, we optimize production processes to balance high quality and competitive pricing. Additionally, we provide 7×24-hour technical support , and on-site training for operators, ensuring customers’ smooth production.

Quanzhou, China – Jinzuan Technology Co., Ltd, a leading manufacturer of precision stone processing machinery, is pleased to announce the successful delivery of a high-performance 3-axis 4-head stone carving machine to a client in Portugal in December. This shipment underscores Jinzuan's expanding global footprint and commitment to delivering advanced, reliable solutions to the international stone industry. The delivered machine, known for its efficiency and precision, is engineered to handle complex carving, engraving, and milling tasks on natural stone, marble, granite, and engineered stone. Its innovative 4-head design significantly enhances productivity by allowing simultaneous processing of multiple workpieces or large surface areas, making it an ideal solution for workshops aiming to optimize output without compromising on detail and quality. "We are thrilled to see our equipment supporting the craftsmanship and production goals of our partners in Portugal," said a spokesperson for Jinzuan Technology. "This delivery represents more than just a transaction; it's a testament to our dedication to providing robust, technologically advanced machinery that meets the specific demands of the global market. We are confident this machine will bring substantial value to our client's operations." Jinzuan Technology specializes in the research, development, and manufacturing of stone carving machines, focusing on durability, user-friendly operation, and innovative features. The company's products are trusted by fabricators and artisans worldwide for applications in monument making, architectural decoration, countertop processing, and artistic sculpting. This successful delivery to Portugal reinforces Jinzuan Technology's position as a trusted partner for businesses seeking to enhance their production capabilities with state-of-the-art equipment. The company looks forward to fostering stronger relationships across Europe and continuing to drive innovation in stone processing technology. About Quanzhou Jinzuan Technology Co., Ltd: Jinzuan Technology is a professional manufacturer based in Quanzhou, China, dedicated to designing and producing high-quality stone carving and processing machinery. With a focus on precision engineering and customer-centric solutions, Jinzuan serves a diverse international clientele, empowering their creative and industrial projects. For more information, please visit: www.jinzuancnc.com

Read MoreQuanzhou Jinzuan Technology Co., Ltd., a trusted manufacturer of advanced stone processing machinery, has proudly completed the December delivery of a 5-axis bridge cutting machine and a 3-head stone engraving machine to a leading stone fabrication company in Spain. This milestone highlights Jinzuan’s expanding global presence and reinforces the company’s commitment to providing high-precision, automated solutions for the international stone industry. The 5-axis bridge cutting machine delivered this time is a core product of Quanzhou Jingzuan Technology, featuring exceptional precision and efficiency. Equipped with advanced 5-axis linkage technology, it can achieve complex cutting operations on various stone materials such as marble, granite, and quartz. Whether it is curved cutting, bevel cutting, or three-dimensional shape cutting, the machine ensures a cutting accuracy of up to 0.01mm, effectively reducing material waste and improving processing efficiency. Moreover, its stable bridge structure and high-quality guide rails enable long-term continuous operation, greatly enhancing the production capacity of stone processing enterprises. For Spanish customers who focus on high-end stone products for architecture and interior decoration, this 5-axis bridge cutting machine provides a powerful solution to meet their demands for intricate and high-precision stone components. The accompanying 3-head engraving machine is another flagship product of Jinzuan. With three independent engraving heads, it can simultaneously process multiple stone workpieces, significantly increasing production efficiency compared to traditional single-head engraving machines. The machine supports a wide range of engraving patterns and depths, from simple logos and patterns to complex three-dimensional reliefs, fully meeting the personalized customization needs of stone processing enterprises. In addition, its intelligent control system allows for easy operation and precise adjustment, ensuring consistent engraving quality even for long-term batch production. Behind the successful delivery is the unremitting efforts of Quanzhou Jinzuan Technology's professional team. The company has a team of experienced engineers and technical personnel who provide comprehensive services from pre-sales consultation to after-sales support. Before the delivery, the team conducted in-depth communication with the Spanish customer to understand their specific processing needs and customized the most suitable equipment configuration plan. During the installation and commissioning phase, professional technicians were dispatched to the customer's site to ensure the machines were properly installed and operated smoothly. In addition, the company also provides regular maintenance services and technical training to help customers maximize the performance of the equipment and achieve long-term stable production. As a trusted brand in the stone processing equipment industry, Quanzhou Jinzuan Technology has always adhered to the concept of "quality first, customer-centric". Through continuous technological innovation and product upgrading, the company has developed a series of high-quality stone engraving machines that have been widely recognized by customers at home and abroad. This delivery to Spain not only further expands Jinzuan's market share in Europe but also lays a solid foundation for the company to enter more international markets such as Central Asia. Looking forward, Quanzhou Jinzuan Technology will continue to focus on the research and development of stone processing technology, launch more advanced and efficient products, and provide better services to global customers. The company is committed to becoming a global leader in the stone processing equipment industry, promoting the development and progress of the global stone processing industry. For more information about Quanzhou Jinzuan Technology's stone processing machines, please visit the company's official website www.stonecnc.net.

Read MoreQuanzhou Jinzuan Technology Co., Ltd., a leading provider of stone processing machinery, successfully participated in the prestigious Dubai Exhibition held from November 24 to 27. The company's manager led the team to showcase its core product lineup at the event, attracting extensive attention from global visitors and industry peers. Highlighting High-Performance Stone Processing Machines During the exhibition, Jinzuan Technology showcased several flagship machines designed for modern stone fabrication: Stone Engraving Machines: Featuring multi-head synchronized carving, high-precision servo control, and stable heavy-duty frames. These machines support 2D/3D carving, relief engraving, column carving, statue production, and complex artistic stonework. Stone Cutting Machines: Including bridge cutting saws and CNC cutting centers, offering accurate slicing, chamfering, and angle cutting. Their intelligent control systems improve efficiency for countertop production, slab cutting, and architectural stone projects. Profiling Machines (Copy Shaping Machines): Designed for fast and consistent molding of stone profiles, ideal for producing cornices, Roman columns, and decorative architectural elements widely used in Middle Eastern construction. Edge Polishing Machines: Built for smooth edge finishing on marble, granite, and engineered stone, ensuring high output quality for kitchen countertops, steps, and façade cladding. Waterjet Cutting Machines: Suitable for marble, granite, ceramics, porcelain slabs, metal, and glass; Cold-cutting technology avoids thermal deformation and micro-cracks; Capable of intricate patterns, medallions, logos, inlays, and artistic mosaic designs. Strong Market Interest from the Middle East During the four-day exhibition, the company's manager engaged in in-depth communications with numerous potential clients and partners from the Middle East and other regions. Many visitors expressed strong interest in Jingzuan's products, inquiring about technical specifications, customization options, and after-sales service. The face-to-face interactions not only helped promote the company's brand image but also laid a solid foundation for future business collaborations. Reliable operation in harsh working environments High efficiency for mass production Precision suitable for luxury architectural stone designs Competitive pricing with strong after-sales support Speaking about the exhibition, the manager of Quanzhou Jinzuan Technology stated, "Participating in the Dubai Exhibition is a crucial step for us to expand our global market presence, especially in the Middle East, which has a booming construction and stone processing industry. The positive feedback we received here reaffirms our confidence in the competitiveness of our products. We will continue to innovate and improve our machinery to better serve our customers around the world." This participation in the Dubai Exhibition marks another important milestone in Quanzhou Jinzuan Technology's international development journey. The company looks forward to leveraging the opportunities from this event to strengthen its position in the global stone processing machinery market and achieve further growth.

Read MoreQuanzhou Jinzuan Technology Co., Ltd., a leading manufacturer of stone engraving machines and intelligent stone processing solutions, announced the successful delivery of its high-performance 6-head Round Carving Machine to a major stone enterprise in Uzbekistan this October. This milestone highlights the growing demand in Central Asia for automated, high-efficiency stone carving equipment, especially for Roman columns, balustrades, sculptures, and architectural stonework. The newly delivered six-head rotary carving machine is engineered to meet the evolving needs of Uzbekistan’s fast-developing construction and stone-processing markets. With advanced multi-head synchronized carving, the machine enables simultaneous processing of multiple columns, drastically improving productivity. Its high-precision servo control, heavy-duty cast-steel structure, and 360-degree rotary carving capability allow artisans to achieve fine 3D details, consistent quality, and stable long-term performance—qualities essential for Uzbekistan’s tradition of ornate stone architecture and its rapidly expanding infrastructure sector. Uzbek stone processors have increasingly sought equipment that supports both mass production and artistic craftsmanship. Jinzuan’s 6-head stone carving machine addresses this need by providing: • Faster turnaround for Roman pillars, cylindrical carvings, and decorative stone components • High repeatability for batch production, reducing labor intensity • Stable output suitable for marble, granite, travertine, and other local stone materials This delivery also reflects Jinzuan Technology’s long-standing commitment to professional service. From pre-shipment testing to installation guidance and after-sales support, Jinzuan’s technical team ensures every customer receives a machine ready for efficient operation from day one. The company’s growing presence in Central Asia reinforces its reputation as a reliable supplier of stone engraving machines, multi-head carving machines, and CNC stone machinery known for durability and precision. “We are proud to support our client in Uzbekistan with advanced equipment that enhances both productivity and craftsmanship,” said a spokesperson for Jinzuan Technology. “The successful deployment of this 6-head 3D rotary stone carving machine demonstrates our dedication to helping international customers upgrade their manufacturing capabilities.” As Uzbekistan continues to invest in construction, cultural restoration, and architectural projects, the delivery of this machine marks an important step in accelerating local stone processing modernization. Quanzhou Jinzuan Technology will continue expanding its global service network and providing innovative stone machinery solutions for partners worldwide.

Read MoreXiamen Jingzuanyun Machinery Co., Ltd., a leading machinery manufacturer in China, has officially announced its participation in an international exhibition to be held in Verona, Italy. Running from September 23 to 26, 2025, the exhibition will take place at Via del Lavoro 8, 10148 VR, Verona. At the event, the company will showcase a range of cutting-edge equipment, with its high-performance engraving machines expected to be the highlight of the booth. As one of Xiamen Jingzuanyun Machinery’s flagship products, its engraving machines have gained wide recognition in the industry thanks to multiple innovative designs. It is reported that some models of these engraving machines are equipped with a 180° rotatable worktable – a unique structure that successfully solves the technical challenge of large-angle carving for workpieces such as stone arc plates and flower caps. This design not only enables more complex carving patterns but also meets the diverse production needs of customers in the stone processing and related fields. In terms of hardware configuration, this series of engraving machines also demonstrates high-end quality. The equipment is equipped with full servo motors and reducers, ensuring high speed, high precision, and strong stability during operation. Meanwhile, the adoption of widened imported linear guide rails not only enhances the load-bearing capacity of the equipment but also further guarantees smooth operation and processing accuracy. Additionally, the application of a constant-power spindle motor provides the machine with strong cutting power, effectively improving overall production efficiency. Notably, the CNC system of the engraving machines also features a practical power-off memory function. Even in the event of sudden power failure or tool breakage, the machine can resume and continue the carving process after restarting, avoiding material waste and construction delays. The entire machine is made of steel structure, boasting high rigidity and excellent deformation resistance, with a maximum load-bearing capacity of over 4 tons – capable of adapting to long-term high-intensity production scenarios. In addition to engraving machines, Xiamen Jingzuanyun Machinery will also display other core equipment such as cutting machines and profiling machines at the exhibition. This participation not only provides the company with an important platform to promote its products to global customers but also creates opportunities for technical exchanges and cooperation exploration with international industry partners. Quanzhou Jingzuanyun Machinery stated that it looks forward to letting more international customers recognize the high-quality standards of Chinese machinery manufacturing through this exhibition and further enhance the brand’s international influence.

Read MoreClick to view online and download Tombstone Processing Solution.PDF Introduction: Modernizing Monument Craftsmanship At Quanzhou Jinzuan Technology Co.,LTD, we understand that creating a tombstone is a sensitive and significant task, blending artistry, durability, and efficiency. The traditional methods of hand-carving are time-consuming and limit design possibilities. Our integrated machinery solution leverages advanced technology to revolutionize tombstone production, enabling you to create intricate, high-quality, and personalized monuments with unparalleled precision and speed. This solution is designed for monument workshops and manufacturers looking to enhance their capabilities, increase output, and offer a wider range of products to their clients. The Core Workflow & Machine Integration A seamless tombstone production process can be broken down into three key stages, each supported by our specialized machinery.

Click to view online and download Tactile Paving Stone Processing Solution.PDF Introduction: Paving the Way for Inclusive Cities Tactile paving stones (or "detectable warning surfaces") are a critical safety feature in urban landscapes, guiding visually impaired pedestrians safely through public spaces. The global demand for these standardized, high-quality tiles is rising with increasing urbanization and accessibility awareness. Traditional manufacturing methods struggle with consistency, output, and the precise detailing required for effective tactile guidance. Quanzhou Jingzuan Technology Co.,LTD provides a fully integrated, machine-based manufacturing solution that empowers concrete product manufacturers to produce compliant, high-quality tactile paving stones with superior efficiency and profitability. The Integrated Production Line: From Raw Material to Finished Product Our solution transforms a standard concrete block production line into a specialized, high-value tactile paver factory.

Click to view online and download Stone Countertop Processing Solution.PDF Introduction: Mastering the Art of Countertop Fabrication The modern countertop market demands perfection: complex cuts for sinks and faucets, flawless edge profiles, and seamless integration with appliances. Traditional fabrication methods are prone to human error, leading to material waste, costly reworks, and project delays. Quanzhou Jingzuan Technology Co.,LTD provides a technology-driven fabrication solution that empowers workshops to achieve unmatched precision, elevate finish quality, and significantly boost their production capacity for materials like granite, quartz, marble, and acrylic solid surfaces. The End-to-End Fabrication Workflow Our solution seamlessly integrates into your production line, transforming raw slabs into finished, installation-ready countertops.

leave a message

Scan to Wechat :

Scan to WhatsApp :