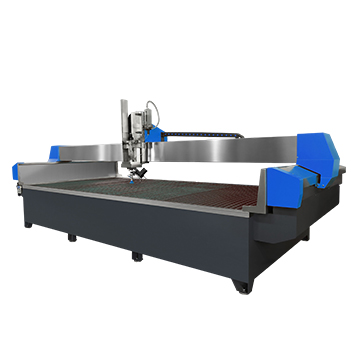

Engineered specifically for the stone processing industry, our High-Pressure Water-Jet Cutting Machine redefines precision, versatility, and efficiency in stone cutting tasks.

Product Model :

NBSD-AB-2515Certification :

CE, ISOSpecifications :

3000*2000Origin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvidedWarranty Period :

1 Year

Leveraging ultra-high-pressure water jet technology combined with optional abrasive integration, this equipment can effortlessly slice through a wide spectrum of stone materials—from hard, dense granite and elegant marble to engineered quartz and fragile artificial stone—without generating heat, cracks, or surface damage. Unlike traditional cutting tools that limit design flexibility, our water-jet machine enables complex, intricate cuts (such as irregular shapes, sharp angles, and fine patterns) while maintaining the natural texture and structural integrity of the stone.

1).Ultra-High-Pressure Cutting Power: Equipped with a high-performance pump that generates pressure , enabling smooth, fast cutting through stone slabs of varying thicknesses without compromising precision.

2).Abrasive & Non-Abrasive Dual-Mode Cutting: Supports both pure water cutting (for soft stone like marble or artificial stone) and abrasive water cutting ( for hard materials like granite or quartz), adapting to diverse stone hardness levels.

3).CNC-Powered Precision Positioning: Features a high-resolution CNC control system with a user-friendly touchscreen interface, supporting CAD/CAM design file imports . It ensures cutting accuracy within ±0.1mm, perfect for complex shapes, curves, and nested cutting .

4).Large Working Table & Flexible Loading: Comes with a spacious working table to accommodate large stone slabs. Optional automatic loading/unloading systems reduce manual labor and minimize workpiece damage during handling.

5).Energy-Efficient & Low-Maintenance Design: Adopts an energy-saving pump with intelligent pressure regulation (reducing energy consumption by 18% compared to conventional water-jet machines) and wear-resistant components (such as ceramic nozzles and high-pressure hoses) that extend service life and lower maintenance costs.

6).Safety & Emergency Protection: Equipped with a fully enclosed cutting chamber, emergency stop buttons, and pressure overload sensors. It automatically shuts down in case of abnormal pressure, water leakage, or abrasive shortage, ensuring operator safety and equipment protection.

Technical Parameters

| Cutting Dimensions and Specifications | 3000*2000mm |

| Feed Height | 110mm |

| The Rotation Range of the Knife Head AB | ±10° |

| Cutting Accuracy | ±0.1mm |

| Processing Speed | 0,5-3.5m/min (depending on the material) |

| Repeatability of Positioning Accuracy | 0.05mm |

| Maximum Feed Rate | 3500mm/min |

| Maximum Free Running Speed | 1000mm/min |

| Motor | Nc Studio |

| Operating Voltage | AC220V/50Hz or AC380V/50Hz |

| Control System | Weihong Bus |

Applications

1).Residential Stone Fabrication: Cutting custom granite/quartz countertops with unique edge profiles , marble bathroom vanity tops, and stone backsplashes for homes, apartments, and luxury villas. Supports personalized designs like integrated sinks or decorative cutouts.

2).Architectural Stone Cladding & Flooring: Producing large-format stone wall panels (for hotel lobbies, office facades) and floor tiles with precise interlocking edges or custom patterns for commercial buildings and residential complexes.

3).Decorative Stone Art & Inlays: Creating delicate stone inlays (for furniture, doors, or wall decorations), intricate stone mosaics, and custom stone sculptures (for galleries, museums, or public spaces) by cutting thin stone sheets into detailed shapes.

4).Monument & Memorial Stone Processing: Cutting granite/marble tombstone slabs into specific sizes, engraving preparation , and shaping memorial plaques with complex designs .

5).Landscape & Outdoor Stone Projects: Cutting large stone blocks into garden features like fountain basins, curved stone benches, pathway stepping stones, and retaining wall blocks. It handles thick stone materials without cracking, ideal for outdoor durability.

6).Commercial Stone Production: Batch cutting standard stone products (e.g., kitchen countertops, shower trays, stone coasters) for wholesale to home improvement stores, interior design firms, and construction contractors. Nested cutting maximizes material usage, reducing waste and lowering production costs.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province.The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :