Multi Head High Efficiency CNC Engraving Machine for Granite/Marble Carving

Tailored exclusively for the stone processing industry, our Four-Head CNC Stone Engraving Machine is a revolutionary solution designed to boost production efficiency while maintaining exceptional precision.

Product Model :

JZY-3020T-4DCertification :

CE, ISOSpecifications :

4300*3200*2100MMOrigin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvidedWarranty Period :

1 Year

Unlike single-head engraving machines, this equipment features four independently controllable engraving heads, enabling simultaneous processing of multiple stone workpieces or synchronized carving of large-scale stone slabs. It integrates advanced CNC technology, high-torque servo motors, and wear-resistant engraving tools, making it suitable for a wide range of stone materials—from hard granite and durable quartz to elegant marble and artificial stone.

1).Four Independent & Synchronizable Engraving Heads: Equipped with four high-performance engraving heads that can operate independently (processing different workpieces) or synchronously (carving large slabs together). This dual-mode operation flexibility maximizes productivity, increasing output compared to single-head machines for batch tasks.

2).High-Precision CNC Control System: Adopts a professional-grade CNC system with 0.01mm positioning accuracy, supporting CAD/CAM design file imports. It enables precise reproduction of complex patterns, fine lettering , and 3D relief carving, ensuring every detail meets design standards.

3).Wide Stone Material Compatibility: Features adjustable engraving speed , spindle power (5.5-7.5KW), and tool compatibility. It efficiently processes various stone types—including high-hardness granite , soft marble, engineered quartz, and even porous travertine—without tool wear or stone surface damage.

4).Intelligent Batch Processing Function: Built-in batch programming software that allows one-time setup for multiple identical workpieces. The machine automatically adjusts the engraving heads’ positions, optimizes processing paths, and minimizes idle time, ideal for mass production of stone products like tombstone plaques, decorative coasters, or standardized wall tils.

5).Robust & Stable Mechanical Structure: Constructed with a heavy-duty cast iron frame and reinforced guide rails, reducing vibration during high-speed engraving and ensuring long-term stability. The anti-deformation worktable supports large or thick stone slabs, preventing workpiece displacement during processing.

6).User-Friendly Operation & Safety Protection: Equipped with a touchscreen display with multilingual support , enabling easy parameter setting and real-time processing monitoring.

7).Energy-Saving & Low-Maintenance Design: Adopts energy-efficient servo motors and an intelligent power management system, reducing energy consumption by 25% compared to traditional multi-head machines. Detachable dust collection ports and wear-resistant components simplify maintenance and lower operational costs.

Technical Parameters

| Model No. | JZY-3020T-4D |

| Platform Dimension | 3000*2000mm |

| Working Size | 650*1900*4mm |

| Feed Height | ≤400mm |

| Air Speed | 20m/min |

| Processing Speed | 20m/min |

| Spindle Speed | 6000-24000rmp/min |

| Spindle Power | 5.5kw~7.5kw variable frequency water cooled spindle |

| Motor | AC digital servo motor |

| Reducer | JZ8098 |

| Control System | N60 |

| Operating Voltage | AC220V/50HZ or AC380V/50HZ |

| Engraving Tool | Φ4/6/8/10/12/14/16mm |

| File Format | G Code/ENG |

| Positioning Accuracy | ±0.02mm |

| Repeatability | ±0.01mm |

| Machine Dimension | 4300*3200*2100mm |

| Weight | 4000kg |

Applications

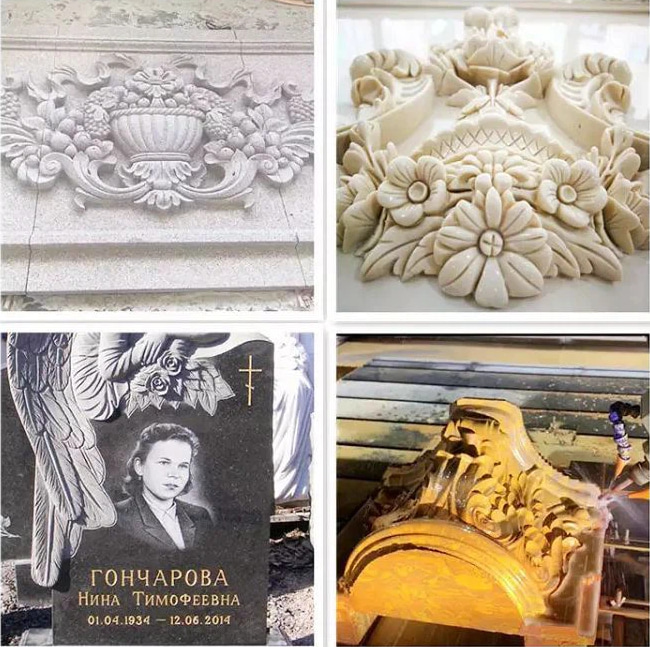

1).Monument & Tombstone Batch Production: Simultaneously engraving names, epitaphs, and decorative patterns (e.g., religious symbols, floral motifs) on 2-4 granite/marble tombstone plaques at once. This significantly shortens production cycles for monument manufacturers handling large orders from cemeteries or funeral service providers.

2).Residential Stone Decoration Processing: Batch carving decorative patterns (e.g., geometric shapes, natural textures) on marble/quartz countertops, bathroom vanity tops, or kitchen backsplashes. The four heads can also process different edge profiles for multiple workpieces, meeting the diverse needs of home improvement projects.

3).Architectural Stone Component Manufacturing: Synchronously engraving uniform decorative elements (e.g., column capitals, wall reliefs) on large stone slabs for commercial buildings, hotels, or historical restoration projects. The machine’s large worktable accommodates oversized stone components, ensuring consistent pattern alignment.

4).Custom Stone Artwork & Gift Production: Creating small-batch custom stone artworks, such as personalized stone coasters, commemorative plaques, or decorative wall hangings. The independent head operation allows engraving different designs on multiple workpieces, catering to niche markets like gift shops or corporate branding.

5).Landscape Stone Marking: Engraving scenic spot introductions, warning signs, or poetic verses on multiple landscape stones (e.g., park boulders, garden stepping stones) at once. The machine’s weather-resistant engraving ensures the markings remain clear even in outdoor environments exposed to rain, sun, and temperature changes.

6).Commercial Stone Product Wholesaling: Mass-producing standardized stone products like stone tiles with decorative edges, stone coasters with brand logos, or small stone sculptures for wholesale to interior design firms, home improvement stores, and construction contractors. The high efficiency helps meet large-volume orders with tight delivery schedules.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province.The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :