Bridge Type Integrated CNC Profiling Machine for Granite/Marble/Quartz

Engineered as a one-stop solution for stone profiling needs, our Bridge-Type Integrated Profiling Machine combines the stability of a bridge structure with the precision of integrated copying technology—redefining efficiency in stone shaping tasks.

Product Model :

JZY-850Certification :

CE, ISOSpecifications :

3200*4900*2200Origin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvidedWarranty Period :

1 Year

From hard, dense granite and durable quartz to soft, elegant marble and artificial stone, it adapts to diverse material properties while maintaining consistent accuracy, enabling seamless execution of curved edge shaping, custom profile copying, and even semi-finishing on a wide range of stone materials.

1).Sturdy Bridge-Style Structure: Adopts a heavy-duty welded steel bridge frame with reinforced guide rails, ensuring minimal vibration during high-speed profiling.

2).High-Precision CNC Copying Technology: Features a high-sensitivity optical or mechanical copying system (accuracy up to ±0.05mm) . The CNC system supports custom profile programming for non-standard shapes like irregular curves, bevels, and grooves.

3).Wide Profile & Edge Compatibility: Handles a full range of stone profiles, including common options and custom designs. It accommodates stone slab sizes and thicknesses , adapting to diverse project needs.

4).Adaptive Material Handling: Equipped with adjustable processing parameters and diamond-tipped profiling tools that optimize performance for different stone hardness levels.

5).Automatic Workpiece Positioning & Clamping: Integrates a laser positioning sensor that calibrates the stone slab’s position in 2 seconds, and pneumatic clamping devices that securely hold workpieces in place during processing.

Technical Parameters

| Platform dimension | 1800*3200mm(customized) |

| Machine stroke | 1100×3300×350mm |

| Stone thickness | 100-1000(customized) |

| Saw blade spacing | 850mm(customized) |

| Driving system | AC servo motor |

| Control system | Independent research and development |

| Spindle power | 15kw |

| Drive system | Y-axis four guide rails, X-axis three rails, Z-axis four guide rail |

| Oil filling system | Automatic oil pot |

| Running instruction | G-code |

| Blade diameter | 300-600mm |

| Operating Voltage | AC380V/50Hz |

| Repeatability | ±0.05mm |

| Weight | 3.5T |

| Machine Dimension | 3200×4900×2200 |

Applications

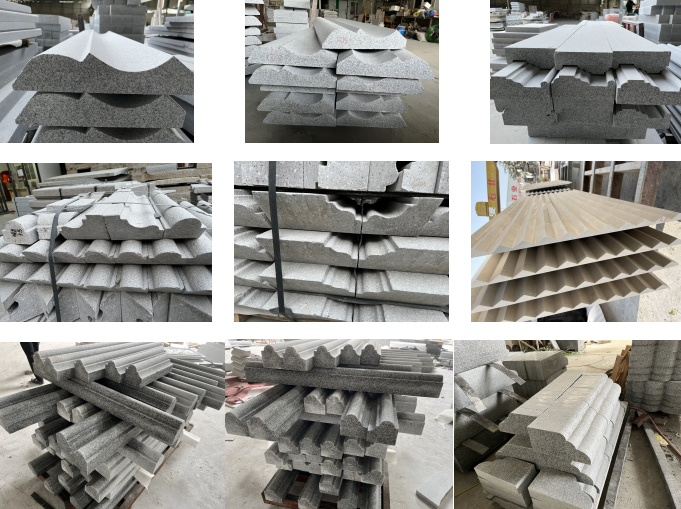

1).Residential Stone Countertop Batch Production: Profiling curved edges on granite/quartz kitchen countertops and marble bathroom vanity tops for home improvement projects.

2).Architectural Stone Component Shaping: Copying custom profiles for stone architectural elements, such as curved column bases, decorative cornices, and window sill edges.

3).Commercial Stone Panel Processing: Shaping large-format marble/granite wall panels with custom edges (e.g., beveled, stepped) for hotel lobbies, shopping mall facades, and office interiors.

4).Decorative Stone Element Fabrication: Creating decorative stone components like curved garden bench tops, stone planter edges, and fountain basin profiles for landscape projects.

5).Monument & Tombstone Profiling: Shaping granite/marble tombstone slabs into custom outlines (e.g., curved tops, irregular borders) and profiling edges for memorial plaques.

6).Custom Stone Furniture Production: Profiling curved edges for stone dining tables, coffee tables, and vanity units.

7).Stone Tile Edge Finishing: Semi-polishing and profiling edges of large stone floor tiles to create interlocking or decorative edges.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province. The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :