High Precision Bridge Type Double Beam CNC Stone Profiling Machine

Designed exclusively for the stone processing industry, our Bridge-Type Double-Beam Profiling Machine redefines efficiency and precision in stone shaping tasks. This advanced equipment integrates robust double-beam construction with intelligent copying technology, enabling seamless replication of complex patterns, curves, and profiles on a wide range of stone materials—including granite, marble, quartz, and artificial stone.

Product Model :

JZY-950Certification :

CE, ISOSpecifications :

4200*4900(The height can be customized)Origin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvidedWarranty Period :

1 Year

The center saw of the saw blade is adjusted to 950, which can process 2 pieces of 880 wide stone.The beam and spindle box are all castings, the power of main motor is 18.5KW, the center distance of saw blade is 950, all servo motor + reducer drive, and the customized system of Power Drill can process two pieces of stone within 880mm at the same time.

1).Dual-Beam Stability: Equipped with heavy-duty bridge-type double beams, the machine offers exceptional structural rigidity, reducing vibration during high-speed operation and ensuring precise profiling even for large or thick stone workpieces.

2).Intelligent Copying Technology: Adopts high-sensitivity optical or mechanical copying systems that accurately replicate 2D/3D templates, supporting complex shapes like arcs, bevels, grooves, and decorative engravings.

3).Multi-Material Compatibility: Optimized cutting and shaping mechanisms adapt to different stone hardness levels—from soft marble to hard granite—without compromising processing quality or tool lifespan.

4).Automated Operation: Features a PLC control system with a touchscreen interface, allowing operators to set parameters (speed, depth, profile type) easily; automated feeding and positioning functions reduce manual intervention and human error.

5).Waste Reduction & Cost Efficiency: Precise material positioning and cutting paths minimize stone waste, while energy-saving motors and low-maintenance components lower long-term operational costs.

6).Safety & Ergonomics: Equipped with emergency stop buttons, protective covers, and anti-slip worktables to ensure operator safety; the machine’s compact design optimizes workshop space utilization.

Technical Parameters

| Platform dimension | 4200*4900(customized) |

| Machine stroke | 1500×3500×500mm |

| Stone thickness | 100-1000(customized) |

| Saw blade spacing | 950mm(customized) |

| Driving system | AC servo motor |

| Control system | Independent research and development(customized) |

| Spindle power | 18.5kw |

| Drive system | Y-axis four guide rails, x-axis dual rails+guide wheels , z-axis four guide columns |

| Oil filling system | XY Oil-immersed type |

| Running instruction | G-code |

| Blade diameter | 500-800mm |

| Operarting Voltage | AC380V/50Hz |

| Repeatability | ±0.05mm |

| Weight | 8T |

| Machine Dimension | 4220*4900(The height can be customized) |

Applications

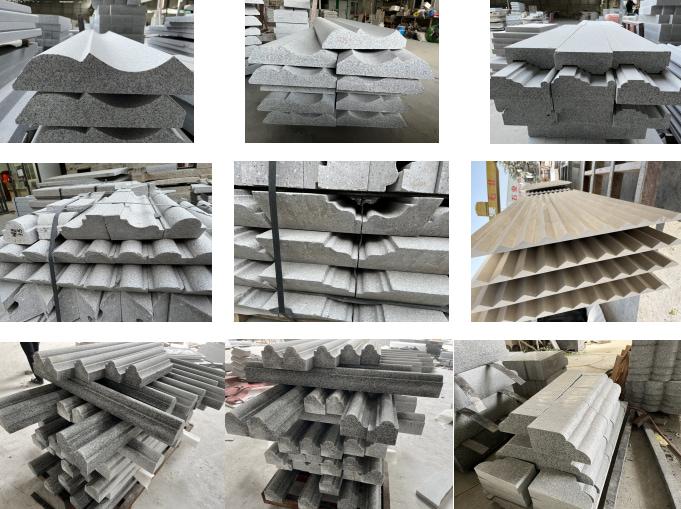

1).Residential Stone Processing: Production of custom marble/granite countertops, kitchen backsplashes, bathroom vanity tops, and window sills for homes, apartments, and villas.

2).Commercial & Architectural Projects: Shaping stone panels for hotel lobbies, shopping mall facades, office building interiors, and public square decorative elements (e.g., columns, railings).

3).Monument & Tombstone Manufacturing: Precision copying of intricate patterns, portraits, and inscriptions on granite/marble tombstones, memorial plaques, and mausoleum components.

4).Landscape & Garden Design: Creating decorative stone products like curved garden benches, stone planters, fountain basins, and pathway edging stones for parks, resorts, and private gardens.

5).Custom Stone Artwork: Crafting unique stone sculptures, reliefs, and artistic decorations for galleries, museums, or high-end interior design projects.

6).Large-Scale Stone Factories: High-volume processing of standard or customized stone products for wholesale to construction companies, interior designers, and home improvement retailers.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province.The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :