Designed exclusively for the precision processing of columnar stone workpieces, our CNC Stone Circular Carving Machine redefines the efficiency and accuracy of Roman column, cylinder, and pillar fabrication.

Product Model :

JZY20080-4DCertification :

CE,ISOSpecifications :

4200*2950*2200mmOrigin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvidedWarranty Period :

1 Year

This specialized equipment combines a robust frame with advanced circular carving technology, enabling seamless 360° shaping, pattern engraving, and detail refinement on cylindrical stone materials—from hard granite and durable quartz to elegant marble and artificial stone.

1).Bridge-Style Stable Structure: Constructed with a welded steel frame and high-precision linear guide rails, ensuring minimal vibration during high-speed circular carving. The bridge’s stable movement along the column’s length guarantees uniform pressure and consistent profile accuracy (±0.1mm) for long workpieces.

2).360° Circular Carving System: Equipped with a rotating workbench (C-axis, 360° continuous rotation) and a vertically adjustable carving head (Z-axis), enabling full circumferential processing of cylindrical stones.

3).Intricate Pattern Engraving Capability: Integrates a high-resolution CNC control system compatible with 2D/3D design files, allowing precise replication of classical Roman column details and custom patterns. The system automatically optimizes tool paths to ensure sharp, detailed carvings without over-cutting.

4).Multi-Spindle & Multi-Tool Compatibility: Features multi independent carving spindles (5.5KW each, variable speed 6000-24000rpm) and supports quick tool changes.

5).Column Alignment & Calibration: Built-in laser diameter measurement and automatic centering sensors that scan the stone cylinder’s surface to detect eccentricity and adjust the carving path in real time.

6).Adaptive Material Processing: Adjustable processing parameters optimized for different stone hardness levels.

Technical Parameters

| Product number | JZY20080-4D |

| Processing Size | 2000*800*800 |

| Spindle Power | 4*5.5KW |

| Spindle Speed | 6000~24000rmp/min |

| Dimensions | 4200*2950*2200mm |

| Total Weight | 3300kg |

| Max Processing Speed | 10m/min |

| Precision | ±0.01mm |

| Shank Diameter | φ3.175-φ12.7 |

| Operating Voltage | AC380V/50HZ |

| Number of Spindles | Four PCS |

Applications

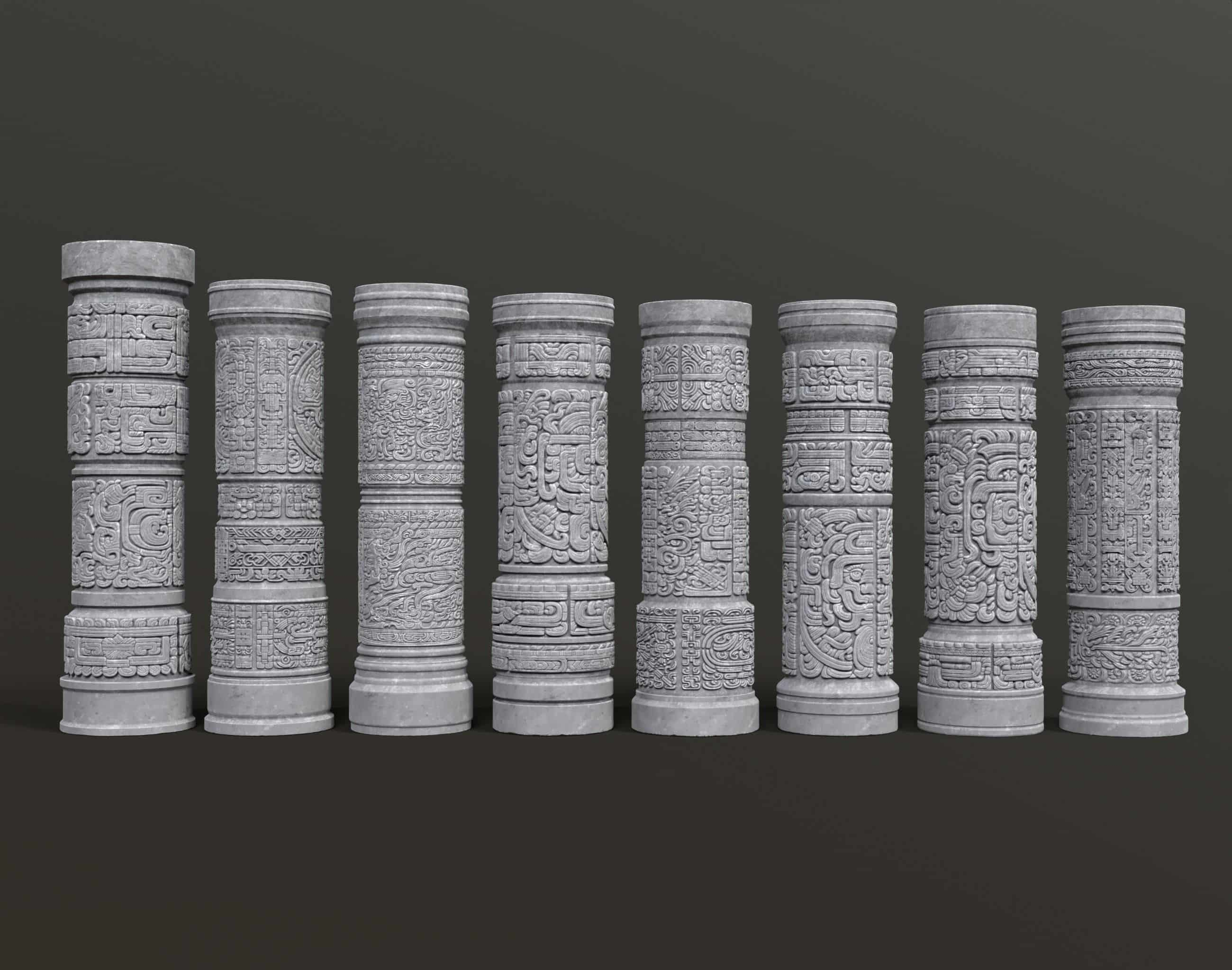

1).Classical Roman Column Fabrication: Producing full-size Roman columns with traditional details for historical building restorations, classical-style villas, and heritage sites.

2).Modern Stone Cylinders for Commercial Spaces: Shaping smooth or textured stone cylinders with clean lines or minimalist patterns.

3).Custom Pillars for Luxury Residences: Creating personalized stone pillars for luxury homes, villa entrances, and backyard pavilions.

4).Monument & Memorial Columns: Carving stone columns for memorial parks, cemeteries, and public monuments—including engraved inscriptions, religious symbols, or 3D relief portraits on the column’s surface.

6).Landscape & Garden Columns: Fabricating decorative stone columns for parks, gardens, and resorts

7).Architectural Column Bases & Capitals: Processing standalone column bases (e.g., square-to-circular transitions) and capitals (e.g., decorative tops for pillars) for construction companies and architectural suppliers.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province.The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :