Tailored to address the critical challenge of breakage in large-format stone engraving, our Automatic Flip-Table Stone Engraving Machine revolutionizes safe and efficient processing of oversized stone workpieces.

Product Model :

JZY-2433SFCertification :

CE, ISOSpecifications :

3500*4300*2200Origin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvidedWarranty Period :

1 Year

At its core is a heavy-duty 90° tiltable worktable, which eliminates the need for manual lifting or repositioning of large stone slabs— a major cause of cracking, chipping, or complete breakage in traditional engraving setups. This advanced equipment integrates CNC precision control with the flip-table design, enabling seamless carving on both flat and tilted surfaces of large-format stones such as granite, marble, quartz, and artificial stone.

1).90° Flip-Table: Equipped with a heavy-duty hydraulic-driven worktable that tilts smoothly from 0° (horizontal) to 90° (vertical). This eliminates manual repositioning of large stone slabs, minimizing stress on the material and reducing breakage risk by over 80% compared to traditional setups.

2).CNC-Powered Precision Engraving: Integrates X/Y/Z linear axes with a high-resolution CNC system (0.01mm positioning accuracy). Supports 2D/3D design file imports and automatic tool path optimization, ensuring sharp details and uniform depth even on large, tilted stone surfaces.

3).Large-Format Stone Compatibility: Designed to accommodate extra-large stone slabs and thick blocks. The flip-table’s anti-slip rubber surface and pneumatic clamping system securely hold oversized workpieces in place during tilting and engraving, preventing shifting that causes breakage.

4).Dual-Side Engraving Efficiency: The 90° flip function enables sequential engraving on both the front and side surfaces of large stones without reloading.

5).High-Power Spindle & Durable Tooling: Features a 5.5-7.5KW variable-speed spindle (6000-24000rpm) with high torque, capable of efficient carving on hard large-format granite. Diamond-tipped tools with heat-resistant coatings maintain sharpness for extended use, reducing tool changes and ensuring consistent results.

Technical Parameters

| Product Number | 2433SF |

| Platform Dimensions | 2400*3300 |

| Workpiece Size | 1140*3200*2 |

| Feed Height | ≤430mm |

| Air Speed | 20m/min |

| Processing Speed | 15m/min |

| Spindle Power | .5~7.5KW*2 |

| Spindle Speed | 6000~24000rmp/min |

| Servo Motor | AC digital servo motor |

| Operating Voltage | AC220V/50Hz or AC380V/50Hz |

| Engraving Tool | φ3.175/4/6/8/10/12.7mm |

| File Format | G Code/HPGL |

| Positioning Accuracy | ±0.02mm |

| Repeatability | ±0.01mm |

| Control System | N60 |

| Mesa (flip) Bear Weight | 500kg |

| Gross Weight | 3500kg |

| Machine Dimension | 3500*4300*2200 |

Applications

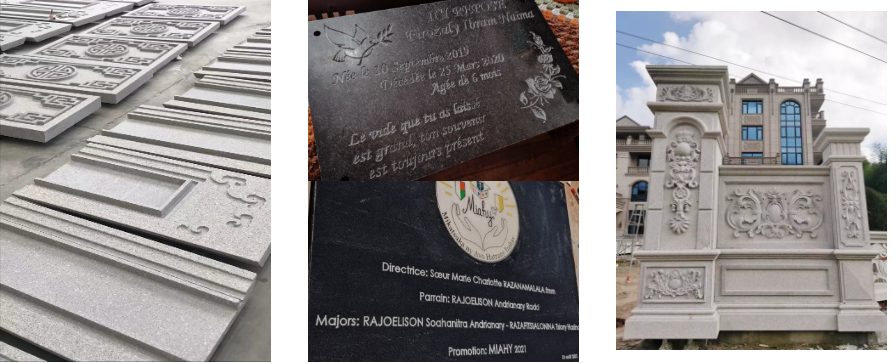

1).Large-Format Architectural Wall Panels: Engraving decorative patterns (e.g., floral reliefs, geometric designs) on oversized marble/granite wall panels for hotel lobbies, shopping mall facades, and office buildings. The flip-table safely tilts panels to engrave edges, eliminating breakage during manual repositioning.

2).Full-Size Stone Countertops: Carving custom edges and decorative cutouts on large quartz/granite countertops ( for luxury homes and commercial kitchens. The anti-slip table prevents cracking during engraving of heavy slabs.

3).Oversized Memorial & Tombstones: Engraving large granite tombstone slabs with portraits, epitaphs, and 3D reliefs. The 90° flip enables engraving on the slab’s face and side without reloading, reducing breakage risk for valuable memorial stones.

4).Public Space Stone Art Installations: Creating large-scale stone artworks (e.g., 3D carved murals, decorative stone screens) for parks, museums, and public squares. The flip-table handles oversized stone blocks safely, allowing artists to execute complex designs on large surfaces.

5).Commercial Stone Flooring Tiles: Engraving patterns on large-format stone floor tiles for high-end retail stores and luxury resorts. The machine’s precision ensures uniform pattern alignment across multiple large tiles, while the flip-table prevents breakage during processing.

6).Curved Large-Stone Components: Engraving on slightly curved large stone components (e.g., arc building facades, curved stone benches) by tilting the table to match the workpiece’s contour. This avoids forcing the stone into unnatural positions that cause cracking.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province. The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :