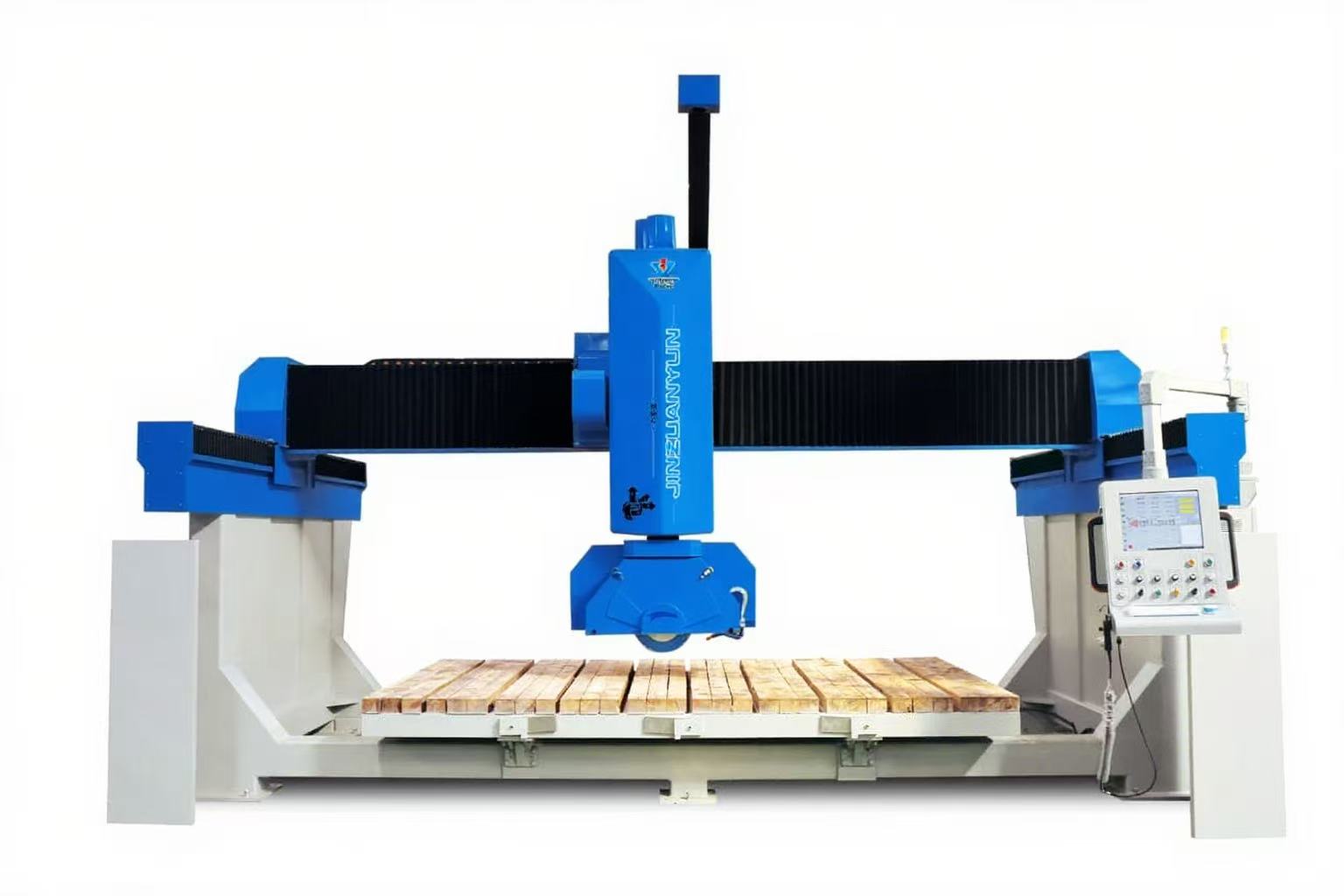

The 5-axis bridge integrated cutting machine is a state-of-the-art industrial solution engineered for high-precision cutting across diverse materials. Combining a robust bridge structure with advanced 5-axis simultaneous motion technology, it delivers superior accuracy, speed, and stability for both complex shapes and large-scale cutting tasks. Equipped with intelligent CNC controls and durable components, making it a reliable choice for factories, processing plants, and fabrication workshops globally.

Product Model :

JZYTJ-600Certification :

CE, ISOSpecifications :

6300*3300*3850mmOrigin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvidedWarranty Period :

1 Year

1).5-Axis Synchronized Cutting: Achieves seamless 3D cutting with complex angles and curves, reducing material handling and improving production efficiency.

2).High-Power Cutting System: Integrates a high-frequency laser or plasma cutting module (optional) with adjustable power, ensuring clean cuts on thick and thin materials.

3).Heavy-Duty Bridge Structure: Constructed with high-strength steel, providing strong load-bearing capacity and minimal deformation during long-term operation.

4).Precision Linear Guides: Equipped with imported linear guides and ball screws for smooth movement, ensuring positioning accuracy within ±0.02mm.

5).Intelligent CNC Control: Supports automatic nesting, path optimization, and remote programming, reducing manual intervention and material waste.

6).Safety Protection System: Includes emergency stop buttons, protective enclosures, and overheat alarms to ensure operator safety and machine reliability.

Technical Parameters

| Project | Parameter | |

| The machine stroke | X axis stroke (mm) | 3400 |

| Y axis stroke (mm) | 2000 | |

| Z axis stroke (mm) | 500 | |

| A axis stroke (°) | 0-90 | |

| C axis stroke (°) | ±365 | |

| Cutting thickness (mm) | 0-210 | |

| General Configuration | Fast running speed (m/min) | 25 |

| Spindle power (kw) | 18.5-22 | |

| Spindle speed (rpm) | 0-3500 | |

| Saw blade diameter (mm) | 300-700 | |

| Platform size (mm) | 3400*2000 | |

| Flip angles (°) | 0-85 | |

| The total power (kw) | ≈33 | |

| The total weight (kg) | ≈7500 | |

| Equipment dimensions (mm) | 6000*3300*3850 | |

| Function Configuration | Camera function | Yes |

| Knife function | Optional | |

| Thickness function | Optional | |

| Chuck function | Optional | |

| Cutter function | Optional | |

Applications

1).Metal Fabrication: Cutting carbon steel, stainless steel, aluminum alloy, and copper sheets for automotive parts, construction components, and industrial machinery.

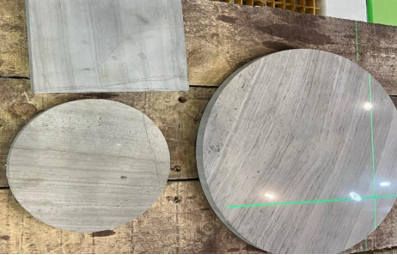

2).Stone Processing: Precision cutting of marble, granite, and quartz stone for countertops, flooring, and architectural decorations.

3).Composite Material Cutting: Handling fiberglass, carbon fiber, and foam composites used in aerospace, marine, and sports equipment manufacturing.

4).Sheet Material Cutting: Producing complex-shaped sheet metal parts for electrical appliances, medical devices, and HVAC systems.

5).Advertising & Signage: Cutting metal and acrylic sheets to create custom signs, lettering, and decorative elements.

6).Construction & Infrastucture: Fabricating steel structures, metal brackets, and prefabricated components for building projects.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province.The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :