Our 4-axis stone cutting machine is designed for precision, versatility, and high-efficiency cutting of stone materials. With advanced CNC technology, it ensures superior accuracy and long-term reliability in demanding environments. Ideal for stone manufacturers looking for enhanced productivity and minimal downtime.

Product Model :

JZQ-400(4 Axis)Certification :

CE, ISOSpecifications :

5000X3000X2700mmOrigin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvideWarranty Period :

1 Year

The 4-Axis Stone Cutting Machine is engineered for fabricators who need to bridge the gap between standard bridge saws and complex 5-axis workstations. Unlike entry-level 3-axis cutters that struggle with mitered edges, this CNC stone machinery features a specialized rotating head that maintains a constant ±0.01mm tolerance even when processing 3000mm-long slabs.

Whether you are working with natural granite, delicate marble, or ultra-hard sintered stone, the reinforced crossbeam ensures vibration-free operation during high-speed automated stone fabrication.

Core Features

1). Dynamic 0°–360° Head Rotation: Enables seamless 45-degree miter cutting for "waterfall" countertops without manual repositioning, reducing labor time by 40%.

2). Heavy-Duty Monoblock Structure: The frame is heat-treated to prevent deformation, ensuring the machine maintains industrial-grade alignment for over 10 years of continuous use.

3). Intelligent PLC Control System: Features a user-friendly interface that supports direct import of DXF files, allowing operators to go from CAD drawing to finished cut in under 5 minutes.

4). Precision Laser Alignment: An integrated green-light laser guide allows for material optimization, minimizing off-cut waste by up to 15% per slab.

Technical Parameters

| Product Number | JZQ-400 3-aixs | JZQ-400 4-aixs | JZQ-400 (4+1) |

| Blade Diameter | φ250~350 | φ250~350 | φ625 |

| Maximum Processing Size | 3200*2000*50 | 3200*2000*50 | 3200*2000*180 |

| Worktable Dimension | 3200*2000 | 3200*2000 | 3200*2000 |

| Blade Rotating Degree | 0~90 | 0~360 | 0~360 |

| Blade Max Chamfering Degree | 0~45 | 0~45 | 0~45 |

| Worktable Tilting Degree | 0~85 | 0~85 | 0~85 |

| Worktable Rotation angle | Optional | Optional | Optional |

| Water Consumption | 4 | 4 | 4 |

| Main Motor Power | 11 | 15 | 18.5 |

| Total Power | 16.2 | 24.5 | 28.9 |

| Weight | 3500 | 3700 | 4000 |

| Overall Dimensions | 5000*3000*2700 | 5000*3000*2700 | 5500*3150*3430 |

Applications

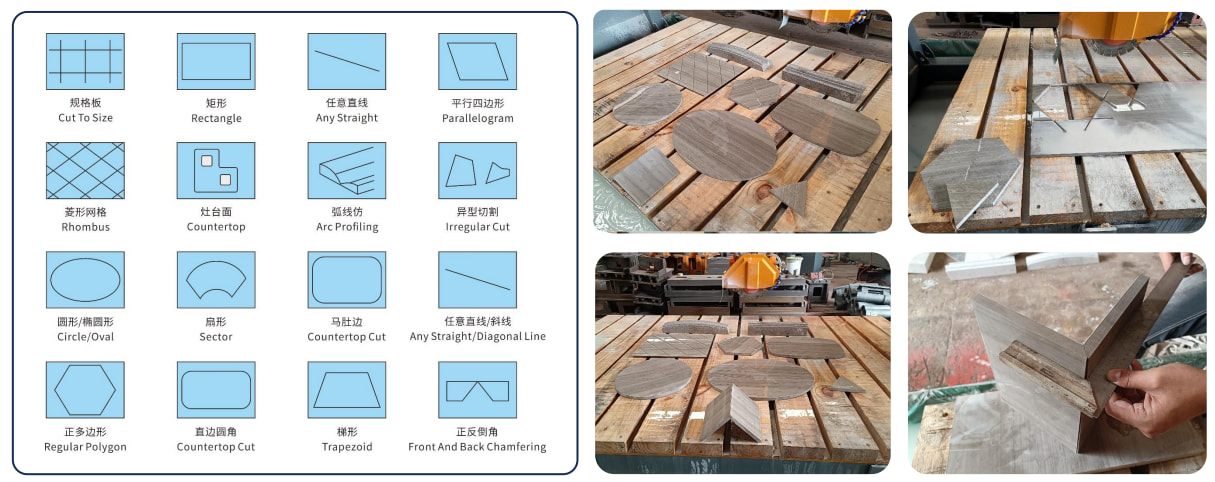

1. Seamless "Waterfall" Countertop Fabrication: High-end kitchen islands and bathroom vanities using Sintered Stone or Marble.

2. Complex Architectural Arches & Radial Facades: Production of curved stone window frames, arched doorways, and circular exterior wall cladding

3. High-Efficiency Sink Hole & Internal Milling: Mass production of commercial vanity tops requiring precise sink cutouts and faucet holes.

4. Large-Format Floor Medallions & Inlays: Creating intricate geometric patterns and borders for hotel lobbies and luxury villas.

5. Monument & Tombstone Shaping: Specialized shaping of headstones, including curved tops, beveled edges, and base moldings.

Expert Q&A

Q1: How does this machine handle the high hardness of Sintered Stone?

A: Our 4-axis cutter utilizes a high-torque, frequency-controlled spindle. When paired with the correct diamond blade, it maintains a stable peripheral speed to prevent edge chipping, a common failure point in lower-tier equipment.

Q2: What certifications are provided for export to the US and EU markets?

A: All our machines are CE certified and use UL-compliant electrical components (such as Schneider) to ensure they meet the rigorous safety and insurance standards required in North America and Europe.

Q3: Why is the monoblock design better than a concrete-foundation install?

A: The monoblock design allows for rapid installation (usually within 24 hours of delivery) and ensures the machine remains a portable asset. It eliminates the risk of "foundation settling" which often causes 3-axis and 4-axis machines to lose accuracy over time.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province.The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :