Introducing our professional 3-Axis Stone Cutting Machine—a dedicated solution engineered to redefine accuracy and efficiency in stone processing. Tailored exclusively for cutting granite, marble, limestone, and other natural stone materials, this machine leverages a stable 3-axis (X, Y, Z) motion system to deliver clean, consistent cuts across flat surfaces and linear profiles.

Product Model :

JZQ-400Certification :

CE, ISOSpecifications :

5000*3000*2700Origin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvideWarranty Period :

1 Year

Unlike generic cutting tools, it’s built with stone-specific durability: from its wear-resistant cutting components to its anti-vibration base, ensuring it handles the rigidity of hard stone without compromising precision.

Whether you’re slicing stone slabs into standard sizes, trimming edges for architectural projects, or creating uniform linear cuts for decor elements, this 3-axis machine balances user-friendly operation with industrial-grade performance, making it ideal for stone workshops, construction sites, and decor manufacturers aiming to streamline their cutting workflows.

1).3-Axis Precision Motion System: Operates on X, Y, and Z axes with high-precision ball screws and guide rails, enabling accurate flat cutting, edge trimming, and linear slotting—with a positioning accuracy of up to ±0.1mm for consistent results.

2).Stone-Specific Cutting Mechanism: Equipped with a heavy-duty spindle and compatible with diamond-tipped blades, it adjusts cutting speed and pressure based on stone hardness to minimize chipping and ensure smooth, burr-free edges.

3).Robust & Stable Construction: Features a thickened steel frame and anti-vibration damping pads to reduce movement during high-load cutting, preventing blade deflection and extending the lifespan of critical components.

4).Intuitive Operation Interface: Integrates a digital control panel with pre-set cutting programs and real-time parameter monitoring.

5).Efficient Workflow Design: Includes a large worktable (customizable size options) to accommodate full-size stone slabs.

Technical Parameters

| Product Number | JZQ-400 3-aixs | JZQ-400 4-aixs | JZQ-400 (4+1) |

| Blade Diameter | φ250~350 | φ250~350 | φ625 |

| Maximum Processing Size | 3200*2000*50 | 3200*2000*50 | 3200*2000*180 |

| Worktable Dimension | 3200*2000 | 3200*2000 | 3200*2000 |

| Blade Rotating Degree | 0~90 | 0~360 | 0~360 |

| Blade Max Chamfering Degree | 0~45 | 0~45 | 0~45 |

| Worktable Tilting Degree | 0~85 | 0~85 | 0~85 |

| Worktable Rotation angle | Optional | Optional | Optional |

| Water Consumption | 4 | 4 | 4 |

| Main Motor Power | 11 | 15 | 18.5 |

| Total Power | 16.2 | 24.5 | 28.9 |

| Weight | 3500 | 3700 | 4000 |

| Overall Dimensions | 5000*3000*2700 | 5000*3000*2700 | 5500*3150*3430 |

Applications

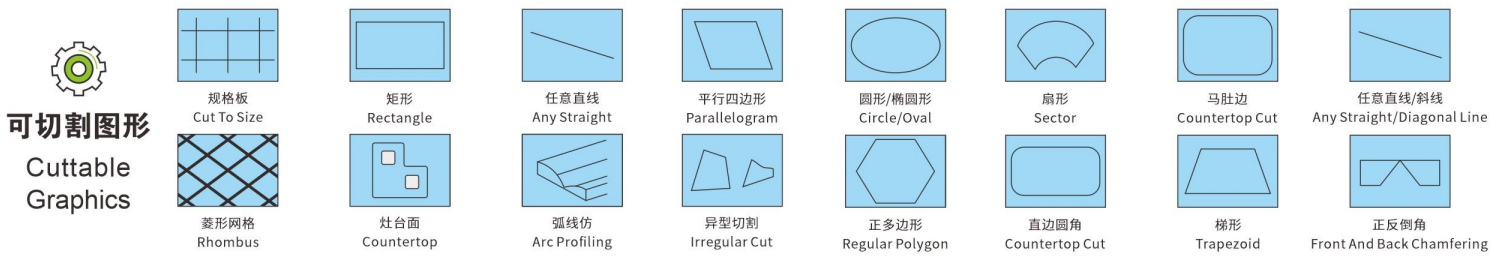

1).Kitchen & Bathroom Countertop Fabrication: Precisely cutting sinks, hob holes, drainer grooves, and shaping edges on granite, marble, and quartz countertops.

2).Tile & Paver Production: Cutting large slabs into customized tiles, mosaic pieces, or patterned pavers with consistent dimensions.

3).Architectural Cladding & Signage: Creating precise components for building facades, interior feature walls, and professional company signage from stone slabs.

4).Monument & Memorial Basics: Efficiently cutting and shaping headstones, plaques, and other memorial elements to required sizes and simple profiles.

5).Custom Furniture & Home Decor: Fabricating stone table tops, shelves, and other decorative elements that require accurate cutting and edge detailing.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province.The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :