What are the main advantages of water jet cutting over traditional bridge saws?

Jan 21, 2026

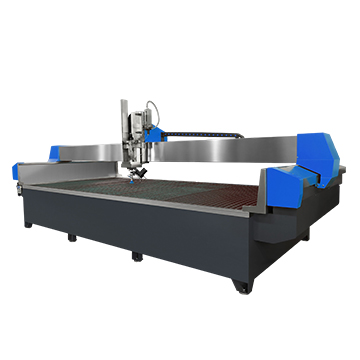

Traditional bridge saw Machine have long been the standard equipment in stone processing. They are efficient for straight cutting of granite, marble, and quartz slabs. However, with the growing demand for customized architecture, artistic stone, and complex designs, more factories are now adopting water jet cutting machines to expand their production capabilities.

This article compares water jet cutting Machine and traditional bridge saws from a practical, factory-use perspective.

1. Cold Cutting: No Heat, No Micro-Cracks

Bridge saws cut stone with high-speed diamond blades, generating temperatures that may exceed 200°C, often causing edge chipping and hidden micro-cracks, especially on thin sintered stone.

Water jet cutting uses ultra-high-pressure water mixed with abrasive (up to 380–420 MPa). The process is completely cold, producing:

No thermal damage

No structural stress

Cleaner edges

Higher finished-product yield

Typical application: sink openings and thin porcelain slabs where breakage risk must be minimized.

2. Complex Shapes and Internal Cutting

Bridge saws are mainly suitable for straight or simple angle cuts. Complex curves and inner holes usually require secondary CNC processing.

Water jet machines can directly cut:

Curves and arcs

Internal holes (without pre-drilling)

Sharp corners

Logos, medallions, and mosaics

Cutting accuracy can reach ±0.05 mm.

Typical application: hotel floor medallions, curved stair steps, artistic wall panels.

3. One Machine for Multiple Materials

Bridge saws are mainly limited to stone.

Water jet cutting can process:

Marble, granite, quartz

Porcelain and sintered stone

Glass and laminated glass

Stainless steel and aluminum composites

Typical application: aluminum honeycomb stone panels and glass-stone composite panels.

4. Better Edge Quality, Less Rework

After bridge saw cutting, slabs often require heavy grinding and corner repair.

Water jet cutting produces:

Narrow kerf (0.8–1.2 mm)

Minimal chipping

More uniform vertical edges

In many countertop projects, only light polishing is needed.

5. Objective Comparison

Aspect

Water Jet Cutting

Traditional Bridge Saw

Cutting principle

Cold erosion (no heat)

High-speed mechanical blade

Shape capability

Any shape, internal holes, curves

Mainly straight or simple geometry

Edge quality

Smooth, minimal chipping

Often needs secondary grinding

Material range

Stone, metal, glass, composites

Mainly stone

Precision

±0.05 mm achievable

±0.2–0.5 mm typical

Custom projects

Highly suitable

Limited

Initial investment

Higher

Lower

Production positioning

High-end, customized, complex

Standard slab processing

Bridge saws remain ideal for high-speed straight cuts. Water jets are superior for high-value, complex, and multi-material projects.

6. Frequently Asked Buyer Questions

Q1: Can a water jet replace a bridge saw completely?

No. In most factories, water jets complement bridge saws. Bridge saws handle fast straight cutting, while water jets handle:

Sink openings

Curves

artistic patterns

thick or fragile materials

The most competitive workshops usually operate both systems.

Q2: Is water jet cutting slower than bridge saw cutting?

For straight lines, yes.

For complex shapes, water jets are often faster overall, because they eliminate:

secondary CNC milling

manual drilling

extensive edge correction

Total project lead time is often shorter.

Q3: What type of stone factory benefits most from water jets?

Countertop factories

Architectural stone suppliers

Custom stone workshops

Mosaic and medallion producers

Export-oriented factories handling diversified orders

Q4: Does water jet cutting weaken stone strength?

No. On the contrary, because there is no heat-affected zone, water jet cutting preserves natural material strength better than blade cutting.

Q5: What thickness range can a water jet handle?

Thin porcelain: 3–6 mm

Standard stone slabs: 15–30 mm

Thick stone: 80–150 mm (depending on pump pressure and nozzle system)

7. Buyer Insight from Export Projects

From actual foreign trade experience, buyers who invest in water jet systems are usually upgrading toward:

Higher-end architectural projects

OEM services for designers

Custom kitchen and bathroom solutions

Diversified material processing

Their biggest gains are not only cutting capability, but order competitiveness. Many report that after adding water jet cutting, their quotation success rate for complex projects increases significantly.

8. Waterjet cutting effect demonstration

9. Conclusion: Why More Stone Factories Are Choosing Water Jet Technology

While traditional bridge saws remain essential for high-speed straight cutting, water jet machines provide clear, measurable advantages in:

Material safety

Shape freedom

Multi-industry capability

Edge quality

Custom project profitability

For modern stone factories aiming to move from price competition to technical and solution-based competition, water jet cutting is no longer an optional upgrade — it is becoming a strategic investment.

Read More