Stone Carving 2.0: The Rise of the 4-Axis, Dual Spindle Workhorse

Nov 26, 2025

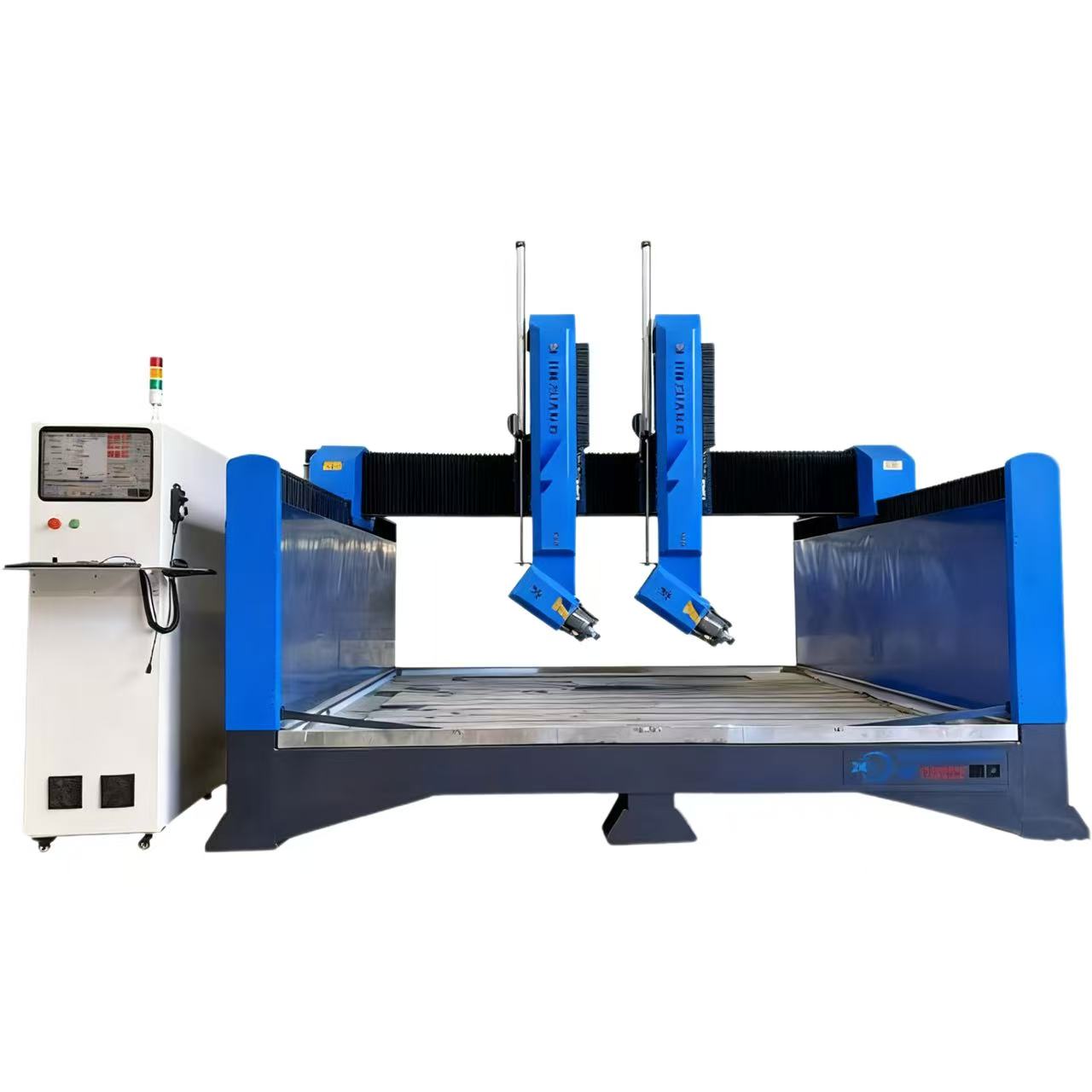

Stone carving, an ancient craft that dates back millennia, has entered a new era of technological sophistication. Among the latest innovations transforming this industry is the 4-axis dual-head stone CNC machine – a remarkable piece of engineering that combines precision, efficiency, and versatility. With two independent swing carving heads capable of rotating 180°, this machine is redefining what’s possible in stone fabrication and artistic engraving. In this post, we’ll explore its features, applications, and why it’s becoming an indispensable tool for modern workshops.

Key Features and Technical Specifications

1. Dual Swing Carving Heads

The most distinctive feature of this machine is its two independently controlled swing carving heads. Each head can rotate 180° along the A-axis, enabling multi-angle carving without the need for manual repositioning of the stone. This capability allows for intricate undercuts, detailed relief work, and complex geometries that were once time-consuming or impossible with traditional 3-axis machines.

2. 4-Axis Motion Control

Unlike standard 3-axis CNCs (X, Y, Z), this machine adds a fourth rotational axis (A-axis). Combined with the dual heads, it offers:

Simultaneous 4-axis machining for continuous carving on curved surfaces.

Enhanced toolpath flexibility, reducing the need for multiple setups.

Improved surface finish on complex contours, such as statues, columns, or architectural moldings.

3. High-Precision Components

Linear guides and ball screws ensure minimal vibration and high positional accuracy (±0.02 mm).

High-torque servo motors provide stable power for carving hard materials like granite, marble, and engineered stone.

Automatic tool changers (optional) allow for uninterrupted operation with various tool types (drills, end mills, diamond cutters).

4. Robust Construction

Built with a heavy-duty gantry and reinforced frame, the machine can handle large stone slabs (up to 3000 x 2000 mm) while maintaining rigidity. Dust and water-proofing protect critical components from abrasive stone particles and cooling fluids.

Advantages Over Traditional Machines

1. Doubled Productivity

With two heads working in tandem, the machine can:

Carve two identical pieces simultaneously – ideal for bulk of architectural elements, tombstones, or decorative items.

Perform roughing and finishing in one setup – one head roughs out the material while the other fine-tunes details.

Reduce idle time by alternating heads for tool changes or maintenance.

2. Unmatched Versatility

The 180° rotation of each head enables:

Multi-sided machining in a single clamping, perfect for 3D sculptures, portraits, and intricate relief.

Efficient deep-hole drilling and texturing at oblique angles.

Hybrid operations – combining engraving, milling, and drilling without manual intervention.

3. Material and Cost Efficiency

Optimized toolpaths reduce material waste.

Lower labor costs due to automation and reduced setup time.

Energy savings from efficient spindle usage and faster cycle times.

Applications Across Industries

1. Architecture and Interior Design

Custom wall claddings, columns, and balustrades with complex patterns.

Fireplace surrounds, sinks, and countertops with intricate edges.

2. Memorial and Monument Making

Detailed portrait and lettering on headstones.

Complex shapes like angels, crosses, or abstract forms.

3. Art and Sculpture

Limited-edition stone sculptures.

Public art installations with precise geometric forms.

4. Signage and Branding

3D logos and corporate signage in stone or glass.

Decorative elements for luxury retail spaces.

Software and Workflow Integration

Modern dual-head CNCs are paired with advanced CAD/CAM software that supports:

Simulation of 4-axis toolpaths to prevent collisions.

Head synchronization protocols for optimal load balancing.

Post-processors tailored for stone materials, accounting for tool wear and cooling requirements.

Future Trends and Innovations

The next generation of these machines may incorporate:

AI-driven adaptive machining that adjusts parameters based on real-time feedback.

Integration with 3D scanning for replicating existing artifacts or custom designs.

Enhanced sustainability features, such as water recycling systems and energy recovery.

The 4-axis dual-head stone CNC machine is more than just an upgrade – it’s a paradigm shift in stone processing. By merging dual-head efficiency with 4-axis flexibility, it empowers artisans, fabricators, and artists to push the boundaries of creativity while meeting commercial demands for speed and precision. As technology continues to evolve, one thing is clear: the future of stone carving is automated, innovative, and incredibly precise.

Read More