The Ultimate Guide to Stone Edge Grinding & Polishing Machines: Customization at Its Core

Dec 15, 2025

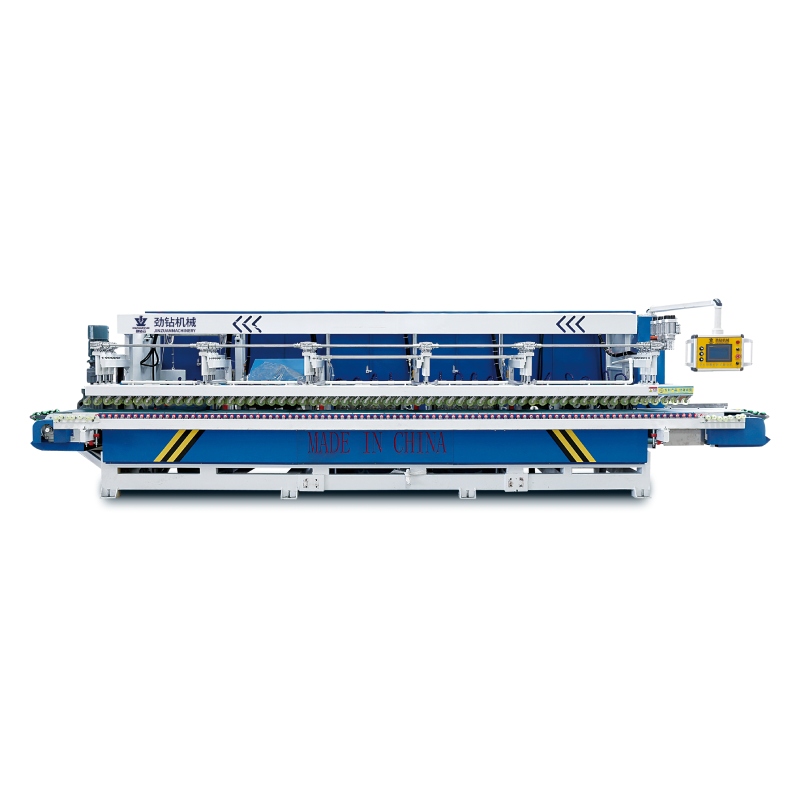

In the world of stone fabrication, precision, efficiency, and versatility are non-negotiable. Whether you're crafting a luxurious marble countertop, a durable granite vanity, or intricate stone tiles, the edge finish can make or break the final product. This is where the modern Stone Edge Grinding and Polishing Machine steps in as an indispensable powerhouse. Today, we’re diving deep into what makes these machines exceptional, with a special focus on one of their most compelling features: customizable (grinding head) configurations, including popular options like 16,18, 20, 22, 24 heads, and beyond or less.

Why Edge Processing Machines Are a Game-Changer

Gone are the days of purely manual edge profiling. Modern stone edge polishers automate the most labor-intensive and skill-dependent part of the process. They ensure:

Unmatched Consistency: Every inch of the edge receives identical treatment.

Remarkable Efficiency: Drastically reduce processing time compared to manual methods.

Superior Quality: Achieve a flawless, showroom-ready polish from rough grinding to final gleaming finish in one continuous sequence.

Operator Ergonomics: Reduce physical strain and allow skilled workers to focus on setup and quality control.

The Heart of the Machine: Understanding the Grinding Head Configuration

The grinding/polishing head, is the business end of the machine. Each head is typically equipped with a different grit diamond polishing wheel or profiling wheel, arranged in a sequential order from coarse to fine.

A standard polishing sequence might look like this:

Rough Grinding (Coarse Grit): Head 1-3 remove major material and shape the profile.

Fine Grinding (Medium Grit): Heads 4-10 progressively smooth the surface.

Polishing (Fine Grit & Buffing): Heads 11-20+ bring out the stone’s natural luster and translucency.

The Power of Choice: Standard & Custom Grinding Head Setups

This is where customization unlocks potential. Manufacturers understand that no two shops are identical. The type of stone (soft marble vs. tough quartzite), the volume of work, and the variety of edge profiles offered (flat, pencil, bullnose, ogee, etc.) all dictate different needs.

Common Standard Configurations:

18-Head Machines: A versatile workhorse for general-purpose shops handling a mix of granites and marbles. Offers an excellent balance of polish quality and cost-effectiveness.

20 & 22-Head Machines: The sweet spot for many high-volume fabricators. The extra heads allow for a more refined progression, often resulting in a superior, deeper gloss, especially on hard stones. They provide more flexibility for specialized wheels.

24+ Head Machines: The premium choice for shops demanding absolute perfection or working with a vast range of materials, including engineered stone. Allows for ultra-gentle transitions between grits and the inclusion of specialty heads for cleaning or sealing stages.

Beyond the Standard: The "On-Demand Customization" Advantage

The true innovation lies in the ability to customize the number and type of grinding head according to your specific needs. This isn't just about adding more heads; it's about optimizing the sequence for your workflow.

Why consider a custom configuration?

Material-Specific Optimization: A shop working predominantly with soft limestone might need a different grit progression than one specializing in quartz conglomerates. You can tailor the wheel types and their order.

Profile Specialization: Complex edge profiles (like intricate Dupont edges) may require additional shaping heads at the start. A custom machine can be built with this in mind.

Future-Proofing: Start with a 20-head setup optimized for your current work, but design the machine frame and control system to allow easy expansion to 24 heads later as your business grows.

Hybrid Processes: Integrate heads for other processes, such as a brushing head for a honed finish or a felt head for final waxing.

Key Features to Pair with Your Custom Configuration

When specifying your machine, grinding head count is just the beginning. Ensure your machine includes:

PLC Touch Screen Control: For easy storage and recall of polishing programs for different materials and edge profiles.

Variable Speed Control: Crucial for adapting to different stone types—slower for resin-rich engineered stone, faster for granite.

Automatic Tilting & Profiling: For consistent shaping of complex edges.

Robust Linear Guideways: Ensure vibration-free movement for a flawless finish.

Powerful & Efficient Motors: Provide consistent torque through all grinding stages.

Investing in Your Shop's Future

Choosing a stone edge grinding and polishing machine with a customizable grinding head setup is a strategic investment. It’s not merely about buying a tool; it’s about engineering a solution that aligns perfectly with your technical requirements, material portfolio, and business vision.

By partnering with a manufacturer that offers this flexibility, you move from a one-size-fits-all approach to a "perfect-fit" solution. You gain a competitive edge through enhanced quality, reduced processing time, and the ability to tackle a broader, more profitable range of projects with confidence.

Ready to transform your stone finishing workflow? Start the conversation by analyzing your most common materials and desired edge profiles. Then, explore machines that can be tailored not just to what you do today, but to what you aspire to accomplish tomorrow.

Have you experienced the difference a customized machine configuration can make? Contact us and share your thoughts!

Read More