This vertical 5-axis CNC stone carving machine is specially engineered for large-scale stone processing, combining high structural rigidity with multi-axis linkage for complex 3D carving. It is widely used for sculpting oversized marble and granite products with high precision, stable long-term operation, and industrial-grade reliability.

Product Model :

LT200150Certification :

CE, ISOSpecifications :

2900*4000*4300Origin :

QuanzhouPort :

XiamenSamples Available :

NoAfter-Sales Service :

ProvideWarranty Period :

1 Year

Designed specifically for the demanding requirements of monumental stone work, this vertical 5-axis CNC stone engraving machine redefines precision and capability in stone fabrication. Its innovative vertical gantry structure provides exceptional stability when machining large, heavy stone blocks, minimizing vibration and deflection to ensure consistent, high-fidelity results.

Unlike conventional 3-axis or even rotary 4-axis machines, the full 5-axis (X, Y, Z, A, C) capability allows the cutting tool to approach the workpiece from virtually any angle in a single setup.

1). True 5-Axis Simultaneous Machining: The core of its capability, enabling the carving of deep undercuts, complex 3D contours, and intricate details in a single clamping. This eliminates the need for multiple setups and manual repositioning of heavy stone blocks, saving days of labor on a single project.

2). Vertical Gantry Structure for Large-Scale Work: Specifically engineered for stability with large, tall workpieces. The vertical design provides superior rigidity against cutting forces, allowing for aggressive material removal in granite while maintaining a footprint optimized for factory floor space.

3). High-Power, Stone-Optimized Spindle System: Equipped with a heavy-duty 22kW liquid-cooled spindle offering high torque at lower RPMs, ideal for driving large diamond tools through dense stone. An automatic tool changer (ATC) with 8-16 stations allows uninterrupted processing from roughing to fine detailing.

4). Advanced Control & 3D Software Suite: Features a user-friendly CNC controller paired with specialized stone carving software. This suite allows seamless import of 3D models (STL, OBJ), automatic toolpath generation, and simulation to prevent collisions—a critical feature for complex, high-value projects.

5). Rugged Construction & Precision Components: Built with oversized, hardened steel linear guides and precision ball screws on all axes. This construction ensures positioning accuracy of ±0.02mm and repeatability of ±0.01mm, guaranteeing that every piece, from the first to the hundredth, is identical.

Technical Parameters

| Product Number | LT200150 |

| Processing size | 1500*1500*2000 (Remarks) |

| Overall dimension | 2900*4000*4300 |

| Processing material size | diameter: 1500, height: 2000 |

| The whole machine weight | 7T |

| Machine Bed | Thickened bridge steel(wall thickness 10) |

| Machine Bridge | Thickened bridge steel(wall thickness 10) |

| Guide rail | Z and y axis PYM-35, x and z axis PYM-30(Taiwan Province) |

| Lead screw | XYZ axis PYM lead screw(Taiwan Province) |

| Transmission mode | X, Y and Z screw drive, A,C-axis turbine reducer |

| Spindle | 22KW(Changzhou) |

| Spindle speed | 24000rm/min |

| Chassis | independent control box |

| System | EPC-100 industrial control system |

| Drive | Digital AC servo motor -1.3KW+Z1.5KW+A4KW (WEIHONG) |

| Motor | Digital AC servo motor -1.3KW+Z1.5KW+A4KW (WEIHONG) |

| Frequency converter | 30KW (RIYE) |

| Lubrication system | Automatic oiling system |

| Operating Voltage | 380V/50HZ |

| File | G-code/HPGL/ENG/MMG/nc/u00 |

| Motion positioning accuracy | 0.02 mm |

| Repeatability | 0.01 mm |

| Feed speed | 12m/min |

| Chip speed | 10m/min |

Applications

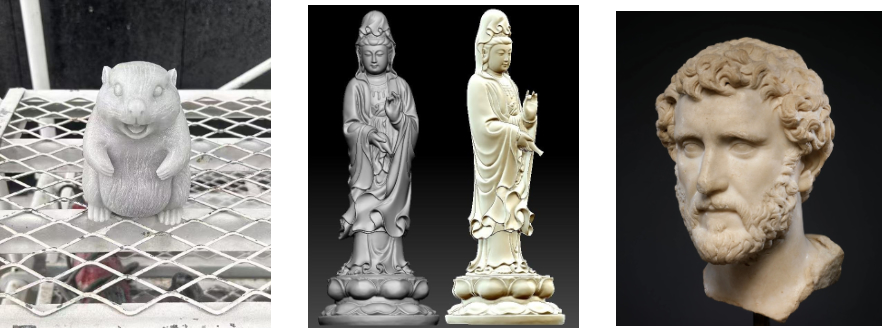

1). Large Marble & Granite Sculpture Production: For statues, monuments, religious carvings, and landscape stone artworks.

2). Architectural Stone Components: Processing columns, Roman pillars, capitals, balustrades, relief walls, and decorative building elements.

3). Memorial & Monument Industry: Tombstones, memorial sculptures, historical monuments, and customized engraving projects.

4). Luxury Interior & Exterior Decoration: 3D stone murals, background walls, hotel lobbies, villas, and high-end commercial spaces.

5). Public Art & Urban Landscaping Projects: Oversized stone artworks for plazas, parks, museums, and municipal engineering.

Vertical 5-Axis vs Traditional 3-Axis Stone CNC

1). 3-axis machines require multiple re-clampings → higher positioning error

2). 5-axis completes complex surfaces in one setup → higher accuracy & efficiency

3). 3-axis struggles with undercuts → 5-axis handles deep curved geometry

4). 5-axis reduces manual finishing → lower labor cost & faster delivery

Frequently Asked Questions

Q1: What types of stone materials can this machine process?

This machine is suitable for granite, marble, quartz stone, limestone, sandstone, and artificial stone. It is especially optimized for high-hardness granite carving and large marble sculptures.

Q2: Why is a 5-axis CNC machine better for large stone sculptures?

5-axis linkage allows the tool to approach the workpiece from multiple angles, enabling undercuts, deep cavities, and complex surfaces to be completed in one operation. This significantly improves carving accuracy and reduces manual grinding.

Q3: Can the machine operate continuously for long production cycles?

Yes. The reinforced bed structure, industrial spindle, and optimized cooling system allow stable 24–72 hour continuous operation, which is critical for large stone projects and factory-level production.

Q4: What is the advantage of the vertical structure for stone processing?

The vertical layout improves stone chip removal, reduces slurry accumulation, enhances tool cooling efficiency, and provides better stability when machining tall or oversized stone workpieces.

Q5: What industries typically use this 5-axis stone carving machine?

Monument factories, architectural stone manufacturers, sculpture studios, urban landscape contractors, and high-end stone processing plants.

Company Profile

Quanzhou Jinzuan Technology Co., Ltd.

Quanzhou Jinzuan Technology Co.,Ltd. is located in Shuitou Industrial Avenue with convenient transportation. It is a company integrating R & D, manufacturing, sales and technical services, specializing in manufacturing a series of intelligent CNC stone processing equipment.

Why Partner Choose Us?

1).Superior Product Quality

2).High Cost Performance

3).Advanced R&D & Technology

4).Comprehensive Customer Support & Service

5).Professional & Experienced Technical Team

6).Global Standards

Certifications

Exhibitions

Our Service

Pre-sale: consulting support

according to customer's requirements to install the machine

visit the factory

After-sale: machine installation and usage guidance

one-year warranty period

FAQ

1.What will the payment process be?

TT : 30% as deposit, 70% before shipping.

2.How many days will take shipping?

About 30 days for production time. Shipping date from Xiamen port to your port need to be check.

3.Who will provide the technical support to installing the device?

1).Our engineer could train you for install and software using and design in our factory for free. One week is enough. Our factory is at Shuitou town, Fujian province. The biggest stone manufacture area in China. Maybe also the biggest importer &exporter of marble all over the world.

2).Our engineer could service you 24 hours online by skype, whatsapp, wechat, facebook message or by cellphone.

3).English manual for machine using and maintaining can be sent.

4).Video for installation and machine using and maintaining can be sent.

leave a message

Scan to Wechat :

Scan to WhatsApp :